SUBJECT VEHICLE: 2005-07 Jeep Liberty.

RESET PROCEDURE? Yes, directions follow.

SPECIAL TOOLS NEEDED? Yes, a thin-walled socket.

The tire pressure monitoring system (TPMS) on the 2005-07 Jeep Liberty uses radio and sensor technology to monitor tire air pressure levels. Sensors, mounted to each road wheel as part of the valve stem, monitor tire pressure, air temperature inside the tires, wheel acceleration and the sensor internal battery status for all four active road tires and the spare (in vehicles equipped with a full-size spare).

The sensor will broadcast this information, along with a unique 32-bit ID, to a central receiver circuit located inside the Wireless Control Module (WCM).

If a warning or fault condition exists, the WCM will send a message that illuminates the low pressure warning light and sounds a chime. If a system fault is detected, the indicator light will flash on/off for 10 to 60 seconds, once every 10 minutes.

To remove a faulty sensor, follow these steps. CAUTION: Wheels and tires are match-mounted at the factory. Before demounting a tire from its wheel, a reference mark should be placed on the tire at the valve stem location.

1. Remove the tire and wheel assembly.

2. Demount the tire from the wheel following the tire changer manufacturer’s instructions. Pay special attention to the following:

a. When breaking front and rear tire beads loose from the wheel rim, avoid using the bead breaker near the sensor.

b. When preparing to demount the tire from the wheel, carefully insert the mounting/demounting tool at the valve stem +/-10 degrees, and then proceed to demount the tire from the wheel.

3. Using a thin-walled socket, remove the special nut retaining the sensor to the wheel. While removing the nut, hold pressure against the rear of the metal valve stem to keep it from pushing rearward, which could damage the antenna strap.

4. Remove the sensor from the wheel.

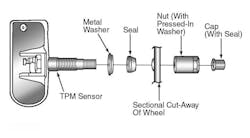

To install a new sensor, follow these steps. NOTE: Before reinstalling an existing tire pressure sensor, replace the seal and the metal washer at the base of the valve stem to ensure proper sealing. See Figure 1.

1. Wipe the area clean around the sensor/valve stem mounting hole in the wheel. Make sure the surface of the wheel is not damaged.

CAUTION: To avoid damaging the sensor antenna strap, hold pressure against the rear of the metal valve stem while the sensor is inserted through the wheel mounting hole and the nut is installed.

2. Insert the sensor through the wheel, keeping pressure against the rear of the metal valve stem. The potted side of the sensor is to be positioned toward the wheel. Do not attempt to mount the sensor otherwise, or damage may occur. Install the sensor nut (with pressed-in washer) by hand. NOTE: Before tightening the sensor nut, push downward on the sensor housing in an attempt to make it flush with the interior contour of the wheel

3. Using a thin-walled socket, install the sensor nut. While holding the sensor in position, tighten the sensor nut to 58 in.-lbs. (6.5 N.m).

4. Mount the tire on the wheel following the tire changer manufacturer’s instructions, paying special attention to the following to avoid damaging the tire pressure sensor.

a. Rotating wheel tire changers — once the wheel is mounted to the changer, position the sensor valve stem 210 degrees from the head of the changer in a clockwise direction before rotating the wheel (also in a clockwise direction) to mount the tire. Use this procedure on both the upper and lower tire beads.

b. Rotating tool tire changers — position the wheel on the changer so that the sensor valve stem is 210 degrees from the head of the changer in a clockwise direction from the mounting end of the tool. Make sure the sensor is clear of the lower bead breaker area to avoid damaging the sensor when the breaker rises. Rotate the tool in a counterclockwise direction to mount the tire. Use this procedure on both the upper and lower tire beads.

5. Adjust the air pressure to specifications. Make sure the original style valve stem cap is securely installed to keep moisture out of the sensor. Install the wheel and tire assembly on the vehicle.

6. Drive the vehicle for a minimum of 10 minutes while maintaining a continuous speed above 15 mph. During this time, the system will learn the new sensor ID code and will clear any DTCs automatically.

Now you are ready to retrain the sensors. NOTE: If a tire pressure sensor has been replaced, the TPMS needs to relearn the tire pressure sensor IDs.

Using an RF signal, each sensor transmits tire pressure data once every minute. Each sensor’s (transmitter) broadcast is uniquely coded so that the WCM can monitor the state of each of the sensors on the four rotating road wheels. The WCM automatically learns and stores the sensor’s ID while driving, after a sensor has been replaced. There is no formal retraining procedure necessary.

On 2005-06 models, drive the vehicle for a minimum of 10 minutes while maintaining a continuous speed above 20 mph. On 2007 models, drive the vehicle for a minimum of 10 minutes while maintaining a continuous speed above 15 mph. On all models during this time, the system will learn the new sensor ID code and will clear any DTCs automatically. If a sensor cannot be trained, see the appropriate manufacturer service information.

Information for this column comes from Mitchell 1’s ”Tire Pressure Monitoring Systems Guide” for domestic and import vehicles through 2010. Headquartered in Poway, Calif., Mitchell 1 has provided quality repair information solutions to the automotive industry for more than 80 years. For more information, visit www.mitchell1.com.