TPMS: Nissan Titan 2004-2018

SUBJECT VEHICLES: 2004 – 2018 Nissan Titan.

RELEARN PROCEDURE? No.

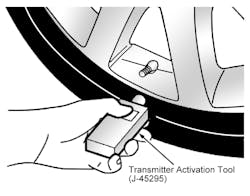

SPECIAL TOOLS NEEDED? A Nissan Signal Tech II scan tool (J-50190) or CONSULT scan tool can be used. A transmitter activation tool (J-45295) is used in the wake-up procedure and can aid in the registration procedure if using the CONSULT tool system.

The tire pressure monitoring system (TPMS) in the 2004 to 2018 Nissan Titan may also be referred to as the low tire pressure warning system. The instrument cluster may also be referred to as combination meter.

During driving at speeds above 25 mph (40 km/h), the low tire pressure warning system receives the signal transmitted from the transmitter installed in each wheel, and gives alarms when the tire pressure becomes low. A sensor-transmitter integrated with a valve (installed on each wheel) transmits a detected air pressure signal in the form of a radio wave. An antenna located in the passenger-side front pillar receives the air pressure signal transmitted by the transmitter in each wheel. The low tire pressure warning control unit reads the air pressure signal received by the antenna, and controls the warning light and the buzzer operations. It also has a judgement function to detect a system malfunction.

Tire pressure warning light

NOTE: Tire pressure rises and falls depending on heat caused by vehicle’s operation and the outside temperature. If the outside temperature is low, the air inside the tire may cool, causing a lower tire inflation pressure. This may cause the low tire pressure warning light to illuminate.

When the low tire pressure warning system detects low inflation pressure or another unusual symptom, the warning light in the instrument cluster comes on. If the system detects that air pressure is less than 27 psi (190 kPa), it will also sound a buzzer for 10 seconds and a “FLAT TIRE” or “CHECK TIRE PRESSURE” warning message will appear in instrument cluster display (if equipped).

The instrument cluster display unit displays the air pressure of each tire (except the spare tire). After the ignition switch is turned on, the pressure values will not be displayed until the data of each wheel is received.

NOTE: Pressure indication in “** psi” on the screen indicates that the pressure is being measured. After a few driving trips, the pressure for all four tires will be displayed. The order of tire pressure figures displayed does not correspond with the actual order of tire position.

When the tire pressure warning light comes on, immediately check the air pressure of all tires and adjust to the specified pressure. Make sure the warning light goes off. The warning light does not automatically turn off when the tire pressure is adjusted.

After the tire is inflated to the recommended pressure, the vehicle must be driven at speeds above 25 mph (40 km/h) to activate the TPMS and turn off the low tire pressure warning light. If the warning light stays on or flashes, there is a malfunction in the TPMS. See the appropriate manufacturer service information.

TPMS reset procedures

NOTE: When a spare tire is mounted, or a wheel, tire pressure sensor or BCM is replaced, the tire pressure sensor must be registered.

The low tire pressure warning light does not automatically turn off when the tire pressure is adjusted. After the tire is inflated to the recommended pressure, the vehicle must be driven at speeds above 25 mph (40 km/h) to activate the TPMS and turn off the low tire pressure warning light.

Tire pressure sensor registration

NOTE: If the tire pressure sensor was replaced, the new sensor will be in an “asleep” mode. To wake up the sensor, see “Transmitter wake-up operation.”

NOTE: To register a new tire pressure sensor, a Nissan Signal Tech II scan tool or CONSULT scan tool can be used. A transmitter activation tool (J-45295) is used in the wake-up procedure and can aid in the registration procedure if using the CONSULT tool system. Sensor registration and wake-up methods in this article reference CONSULT type scan tool procedures.

NOTE: If a CONSULT-II is used without also using the CONSULT-II CONVERTER, a malfunction might be detected during self-diagnosis, depending on which control unit carries-out CAN communication.

NOTE: The Signal Tech II Tool (J-50190) can be used to perform the following:

- Activate the TPMS transmitters.

- Display the TPMS transmitter IDs.

- Display the tire pressure reported by the TPMS transmitter.

- Read the TPMS DTCs.

- Register the TPMS transmitter IDs.

ID registration with the transmitter activation tool

1) With the ignition switch in the OFF position, connect the CONSULT scan tool to the data link connector (DLC). Turn the ignition switch to the ON position.

2) Select “START (NISSAN BASED VHCL).”

3) Touch “BCM” on the “SELECT SYSTEM” screen.

4) Select “AIR PRESSURE MONITOR” on the “SELECT WORK ITEM” screen.

5) Select “WORK SUPPORT” on the “SELECT DIAG MODE” screen, and select “ID REGIST.”

6) With the transmitter activation tool (J-45295) pushed against the front left transmitter tire air valve, press the button for five seconds (see Figure. 1).

NOTE: Be sure to register the IDs in the specified order, or the self-diagnostic results display will not function properly.

7) Register the IDs in the order specified in the tire registration order table. When the registration of each wheel has been completed, a buzzer sounds as indicated in the table, the hazard warning lights or turn signal indicators flash twice, and the indictor light on the activation tool goes from red to green.

Tire registration order,* buzzer will sound:

- Front left once

- Front right 2 times

- Rear right 3 times

- Rear left 4 times

(*2004-07 models only. From 2008 onwards, the buzzer is eliminated.)

8) After completing all ID registrations, press “END” to complete the procedure.

ID registration without the transmitter activation tool

1) With the ignition switch in the OFF position, connect the CONSULT scan tool to the data link connector (DLC). Turn the ignition switch to the ON position.

2) Select “START (NISSAN BASED VHCL).”

3) Touch “BCM” on the “SELECT SYSTEM” screen.

4) Select “AIR PRESSURE MONITOR” on the “SELECT WORK ITEM” screen.

5) Select “WORK SUPPORT” on the “SELECT DIAG MODE” screen, and select “ID REGIST.”

6) Adjust the tire pressure to the values specified in the sensor ID registration tire pressure specifications table below, and drive the vehicle at 25 mph (40 km/h) or more for a few minutes.

Sensor ID registration tire pressure specifications (2004-13)

Tire position Tire pressure - psi (kPa)

Front left 36 (250)

Front right 33 (230)

Rear right 30 (210)

Rear left 27 (190)

Sensor ID registration tire pressure specifications (2014-)

Tire position Tire pressure - psi (kPa)

Front left 35 (240)

Front right 32 (220)

Rear right 29 (200)

Rear left 26 (180)

7) After completing all ID registrations, press “END” to complete the procedure.

8) Inflate all tires to specification.

Transmitter wake-up operation

NOTE: New replacement transmitters are provided “asleep” and must first be “woken up” using transmitter activation tool J-45295 or Signal Tech II Tool J-50190 before ID registration can be performed. Use the following procedure when using the transmitter activation tool J-45295.

1) With the ignition switch in the OFF position, connect the scan tool to the data link connector (DLC). Turn the ignition switch to the ON position.

2) Display the “WORK SUPPORT” screen, and select “ID REGIST.”

3) With the transmitter activation tool (J-45295) pushed against the left front tire air-valve, press the button for five seconds (see Figure 1). Sensor activation must be performed in this order: left front, right front, right rear and then left rear.

As each sensor ID is activated, the hazard warning lights and the TPMS warning light will flash four times, and the scan tool indicator light changes from red to green.

5) Check that the transmitter wake-up procedure for all wheels is completed using the scan tool.

6) After completing the wake up of all transmitters, make sure the TPMS warning light goes out.

Demounting/mounting procedures

CAUTION: The tire should be demounted from the wheel using the tire changer manufacturer’s instructions. Use the following information to avoid damage during the demounting/mounting procedures.

Tire pressure sensor

CAUTION: Do not inject any tire liquid or aerosol tire sealant into the tires, as this may cause a malfunction of the sensors.

Removal

1) Deflate the tire. Unscrew the transmitter retaining nut, and allow the transmitter to fall into the tire.

2) Gently bounce the tire so that the transmitter falls to the bottom of the tire. Place the wheel and tire assembly on the tire changing machine and break both tire beads.

Ensure that the transmitter remains at the bottom of the tire while breaking the bead.

3) Turn the tire so that valve hole is at the bottom, and gently bounce the tire to ensure the transmitter is near the valve hole. Carefully lift the tire onto the turntable, and position the valve hole (and transmitter) 270 degrees from the mounting/demounting head (see Figure 2).4) Lubricate the tire well, and remove the top side of the tire. Reach inside the tire and remove the transmitter (see Figure 3).

5) Remove the second side of the tire as normal.

Installation

1) Place the first side of the tire onto the rim.

2) Mount the transmitter on the rim and tighten the nut to 49 in.-lbs. (5.5 N.m). See Figure 3. NOTE: Do not touch the transmitter with the mounting head.3) Place the wheel on the turntable of the tire machine. Ensure that the transmitter is 270 degrees from mounting/demounting head (see Figure 2).

4) Lubricate the tire well, and install second side of tire as normal. Ensure that tire does not rotate relative to rim.

5) Inflate the tire. Balance the wheel and tire assembly.

6) Install the wheel and tire assembly in the appropriate wheel position on the vehicle.7) Ensure the front wheel alignment is correct. To adjust the neutral position of the steering angle sensor, turn the tires straight ahead and ensure that the steering wheel is in the neutral position. If it is not in the neutral position, go to the next step.

8) Remove the steering wheel and reinstall it correctly.

If the neutral position cannot be attained by repositioning the steering wheel two teeth or less on the steering stem, loosen the tie-rod lock nuts of the steering outer sockets, and then adjust the tie-rods by the same amount in the opposite direction.

9) Register the tire pressure sensor. See “TPMS reset procedures.” ?

Torque specifications

Wheel nut: 98 ft.-lbs., 133 N.m

Tire pressure sensor nut: 60 in.-lbs., 6.8 N.m