SUBJECT VEHICLE: 2009-13 Dodge Charger.

RELEARN PROCEDURE? Yes.

SPECIAL TOOLS NEEDED? A new sensor ID can be programmed directly into the WIN or TPMS module by using a RKE-TPM Analyzer in conjunction with a scan tool.

The tire pressure monitoring system (TPMS) on the 2009-13 Dodge Charger monitors air pressure in the four road tires; pressure in the spare tire is not monitored. There are two tire pressure monitoring systems available, a base system and a premium system. The base system does not specify how many tires are low or where they are located. The premium system does so.

NOTE: If a tire pressure sensor has been replaced, the tire pressure sensors must be retrained. See reset procedures.

The base TPMS consists of tire pressure monitoring sensors attached to each road wheel through the valve stem mounting hole, a central receiver module Wireless Ignition Node (WIN) and an indicator lamp.

The premium TPMS consists of tire pressure monitoring sensors attached to each road wheel through the valve stem mounting hole, a WIN, three wheel sensor transponders located in three of the four wheel wells, an electronic display and an indicator lamp.

The TPMS module decodes the radio frequency (RF) signals transmitted by each of the vehicle’s tire pressure sensors. The decoded information is used to determine if “warning” or “fault” conditions exist within the TPMS.

Warning or fault condition

Upon detection of a warning or fault condition, the WIN will send a request to the module that controls the indicator lamp (and the text display if equipped with the premium system) via the vehicle bus system to illuminate or flash the indicator lamp. Also, upon the detection of a warning or fault condition, the electronic display will automatically send a request to sound the chime.

The WIN will store all warning and fault conditions, placard pressure values and low-pressure threshold values (lamp ON and OFF) in the system’s memory that can be accessed through diagnostic communication. If new sensors are introduced to the vehicle, the data stored for the sensor being replaced will be deleted.

The WIN will store all wheel sensor IDs and locations and faults in memory that can be accessed through diagnostic communication. All other data values transmitted from each active wheel sensor (not the spare tire) shall be stored in the WIN memory. After a sensor has been replaced, the WIN automatically learns and stores the sensor IDs while driving continuously above 15 mph for 10 minutes. The learning sequence will initiate when the vehicle has been stopped for more than 20 minutes. Under the following conditions, the system may not function properly:

• the areas, facilities or devices that use similar radio wave frequencies are located in the vicinity of the vehicle;

• a radio device of similar frequency is used near the vehicle;

• installing some form of aftermarket window tinting that affects radio wave signals;

• a lot of snow or ice is stuck to the vehicle, especially around the wheels or wheel housings;

• using tire chains on the vehicle;

• the battery of the sensor has been depleted (approximate 10-year life span);

• a spare tire is installed;

• a tire without tire pressure sensor is used;

• wheels other than manufacturer factory wheels are used.

TPMS warning indicators

If warning indicators are on continuously due to low pressure in one or more tires, adjust tire inflation to specification. The light will remain on until tire pressure is properly set. After adjusting air pressure in a tire on the vehicle, the vehicle needs to be driven for approximately two minutes above 15 mph for the message or indicator lamp to go out.

If a system fault is detected, a chime will sound, the TPMS indicator (telltale) lamp will flash for 75 seconds and then remain on solid. For vehicles equipped with the premium TPMS, a message that says “CHECK TPM SYSTEM” will appear in the Electronic Vehicle Information Center (EVIC), followed by a graphic display. See appropriate manufacturer service information.

Reset procedures

NOTE: If a tire pressure sensor has been replaced, the tire pressure sensors must be retrained. If warning indicators are on continuously due to low pressure in one or more tires, adjust tire inflation to specification. The light will remain on until tire pressure is properly set. After adjusting air pressure in a tire on the vehicle, the vehicle needs to be driven for approximately two minutes above 15 mph for the message or indicator lamp to go out.

Using an RF signal, each sensor transmits tire pressure data approximately once every minute. Each sensor’s (transmitter) broadcast is uniquely coded so that the system can monitor the state of each of the sensors on the four rotating road wheels. The TPMS automatically learns and stores the sensor’s ID while driving after a sensor has been replaced. There is no formal retraining procedure necessary.

After the vehicle has remained stationary for 20 minutes, drive the vehicle for a minimum of 20 minutes while maintaining a continuous speed above 15 mph. During this time, the system will learn the new sensor ID code and will clear any DTCs automatically. If a sensor cannot be trained, see appropriate manufacturer service information.

NOTE: A new sensor ID can also be programmed directly into the WIN or TPMS module by using a RKE-TPM Analyzer in conjunction with a scan tool. Once the new sensor ID has been programmed, the vehicle will need to be driven above 15 mph until the fault is no longer active (lamp extinguishes) and display is updated (for up to 20 minutes). Using a TPM-RKE Analyzer can take up to a minute to force a transmission from a sensor.

Demounting/mounting procedures

CAUTION: The tire should be demounted from the wheel using the tire changer manufacturer’s instructions. Use the following information to avoid damage during the demounting/mounting procedures.

CAUTION: The TPMS has been optimized for the original equipment tires and wheels. TPMS pressures have been established for the tire size equipped on the vehicle. Undesirable system operation or sensor damage may result when using replacement equipment that is not of the same size, type or style. Aftermarket wheels can cause sensor damage. Do not use aftermarket tire sealants or balance beads if your vehicle is equipped with TPMS, as damage to the sensors may result.

NOTE: If a tire pressure sensor has been replaced, the tire pressure sensors must be retrained.

NOTE: Wheels and tires are match-mounted at the factory. Before demounting a tire from its wheel, a reference mark should be placed on the tire at the valve stem location to ensure that it is remounted in the original position on the wheel. For match-mounting procedures, refer to appropriate manufacturer service information.

NOTE: Tire pressure will vary with temperature by about 1 psi (6.9 kPa) for every 12 degrees Fahrenheit. This condition means that when the outside temperature decreases, the tire pressure will decrease. Tire pressure should always be set based on cold inflation tire pressure (placard pressure). This is defined as the tire pressure after a vehicle has not been driven for more than three hours (and in outside ambient temperature). The tire pressure will also increase as the vehicle is driven; this is normal and there should be no adjustment for this increased pressure.

NOTE: If tires require leak-testing, a water test may be used to check for a leak around the sensor, as long as any water at the valve core is removed when the procedure is completed. Water can be expelled from the core area by pushing in on the core for several seconds, allowing escaping air to drive out any moisture. Reinflate tire as necessary. Install the original valve stem cap.

Tire pressure sensor

CAUTION: Although additional sensors operating at 433 MHz sensors are available and are used in other applications, they are not interchangeable. Always make sure the correct sensor is being used and be sure to replace the sensor with the correct part number.

CAUTION: The cap used on this valve stem contains an O-ring seal to prevent contamination and moisture from entering the valve stem. Retain this valve stem cap for reuse. Do not substitute a regular valve stem cap in its place.

CAUTION: Do not attempt to install a tire pressure sensor in an aftermarket wheel. Use tire pressure sensors in original style factory wheels only. If aftermarket wheels are installed, and therefore do not contain tire pressure sensors, the system will not function properly and the driver will be continuously notified of a system malfunction.

CAUTION: After inspecting or adjusting the tire pressure, always reinstall the valve stem cap. This will prevent moisture and dirt from entering the valve stem, which could damage the tire pressure sensor.

CAUTION: The valve stem used on this vehicle is made of aluminum and the core is nickel-plated brass. The original valve stem core must be reinstalled and not substituted with a valve stem core made of a different material. This is required to prevent corrosion in the valve stem caused by the different metals.

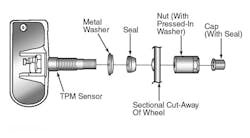

CAUTION: Any time a sensor is to be installed in a wheel, it is necessary to install a new sensor-to-wheel seal, metal washer and valve stem nut, to ensure airtight sealing (see Figure 1).

CAUTION: DO NOT reuse the sensor-to-wheel grommet. Always use a new grommet when installing a pressure sensor and properly torque the sensor nut.

[PAGEBREAK]

Removal

1. Remove the tire and wheel assembly from the vehicle.

2. Demount the tire from wheel following the tire changer manufacturer’s instructions while paying special attention to the following to avoid damaging the pressure sensor:

• When breaking the tire bead loose from the wheel rim, avoid using the bead breaker in the area of the sensor. That includes both front and rear beads of the tire (see Figure 3).

• When preparing to demount the tire from the wheel, carefully insert the mounting/demounting tool 280 degrees plus or minus 10 degrees from the valve stem, and then proceed to demount the tire from the wheel. Use this process on both the upper and lower tire beads.

3. Using a thin-walled socket, remove the special nut retaining the sensor to the wheel. While removing the nut, hold pressure against the rear of the metal valve stem to keep the valve stem from pushing rearward, which could damage the antenna strap (see Figure 2).

4. Remove the sensor from the wheel (see Figure 4).

Installation

NOTE: Before reinstalling an existing tire pressure sensor, replace the seal and metal washer at the base of the valve stem to ensure proper sealing (see Figure 1 found on page 60).

1. Wipe the area clean around the sensor/valve stem mounting hole in the wheel. Make sure the surface of the wheel is not damaged. CAUTION: To avoid damaging the sensor antenna strap, hold pressure against the rear of the metal valve stem while the sensor is inserted through the wheel mounting hole and the nut is installed (see Figures 2 and 4).

2. Insert the sensor through the wheel keeping pressure against the rear of the metal valve stem. The potted side of the sensor is to be positioned toward the wheel. Do not attempt to mount the sensor otherwise, or damage may occur. Install the sensor nut (with pressed-in washer) by hand (see Figure 4).

NOTE: Before tightening the sensor nut, push downward on the sensor housing in an attempt to make it flush with the interior contour of the wheel.

3. Using a thin-walled socket, install the sensor nut. While holding the sensor in position, tighten the sensor nut to 71 in.-lbs. (8 N.m). CAUTION: Over-torqueing the sensor nut by as little as 106 in.-lbs. (12 N.m) may result in sensor separation from the valve stem. Under this condition, the sensor may still function; however, the condition should be corrected immediately.

4. Mount the tire on the wheel following the tire changer manufacturer’s instructions, paying special attention to the following to avoid damaging the tire pressure sensor:

• Rotating wheel tire changers: Once the wheel is mounted to the changer, position the sensor valve stem approximately 280 degrees from the head of the changer in a clockwise direction before rotating the wheel (also in a clockwise direction) to mount the tire. Use this procedure on both the upper and lower tire beads.

• Rotating tool tire changers: Position the wheel on the changer so that the sensor valve stem is approximately 210 degrees from the head of the changer in a clockwise direction from the mounting end of the tool. Make sure the sensor is clear of the lower bead breaker area to avoid damaging the sensor when the breaker rises. Rotate the tool in a counterclockwise direction to mount the tire. Use this procedure on both the upper and lower tire beads.

5. Adjust air pressure to manufacturer’s specification. Make sure the original style valve stem cap is securely installed to keep moisture out of the sensor. Install the wheel and tire assembly on the vehicle.

6. Drive the vehicle for a minimum of five minutes while maintaining a continuous speed above 15 mph. During this time, the system will learn the new sensor ID code and will clear any DTCs automatically. If a sensor cannot be trained, see appropriate manufacturer service information. ■

Information for this column comes from Mitchell 1’s “Tire Pressure Monitoring Systems Guide” for domestic and import vehicles through 2013. Headquartered in Poway, Calif., Mitchell 1 has provided quality repair information solutions to the automotive industry for more than 80 years. For more information, visit www.mitchell1.com.

To read more articles on TPMS, see:

TPMS: Determine the system on a BMW 3-Series E-90