TPMS: 2006-2010 Ford Escape, Explorer, Explorer Sport Trac and Freestar

SUBJECT VEHICLES: Ford Escape 2006-09; Explorer 2006-10; Explorer Sport Trac 2007-10 and Freestar 2006-08.

RELEARN PROCEDURE? Yes.

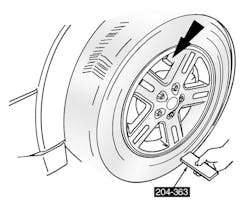

SPECIAL TOOLS NEEDED? Yes. TPMS activation tool (204-363) and a digital tire gauge (204-354).

The tire pressure monitoring system (TPMS) on the 2006-09 Ford Escape; 2006-10 Explorer, 2007-10 Explorer Sport Trac and 2006-08 Freestar monitors the air pressure in the four road tires with wheel-mounted tire pressure sensors. The sensors transmit radio frequency signals to the Smart Junction Box (SJB) approximately every 60 seconds when the vehicle speed exceeds 20 mph (32 km/h), and every six hours when vehicle is stationary.

Each tire pressure sensor transmission is compared against a low-pressure limit (the pressure listed on the vehicle certification label minus 25%, which will be about 6 psi to 9 psi). If it is determined the tire pressure has fallen below this limit, the SJB sends a message to the instrument cluster, which then illuminates the low pressure warning indicator and displays the appropriate message(s) in the message center (if equipped.)

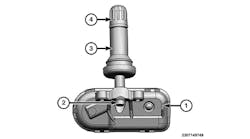

The battery-operated tire pressure sensors are mounted to metal brackets (called cradles) on the wheels inside the tires. The sensors are mounted 180 degrees from the valve stem. The tire pressure sensor may be serviced separately, but the cradle and strap must be replaced together.

Under the following conditions, the TPMS may not function properly:

- Low tire pressure.

- The tire pressure sensor is missing or damaged.

- A spare tire is installed as a road wheel.

- An incorrect tire pressure sensor is installed.

- The tire pressure sensor is installed incorrectly.

- Non-OEM wheels are installed (aftermarket rims).

- Non-OEM equipped run-flat tires are installed.

- There are other non-OEM modifications (roll cages, service barriers, part racks, ladder racks, etc.).

Tire pressure monitor warning indicators

NOTE: As ambient temperature decreases by 6 degrees Celsius (10 degrees Fahrenheit), tire pressure decreases 1 psi (7 kPa). If tire pressures are not adjusted at cold temperature, the tire pressure may drop enough to be detected by the TPMS, which will activate the low pressure warning light.

When the tire pressure warning light comes on and the message center displays “LOW TIRE PRESSURE,” check the air pressure of all tires and adjust to the specified cold pressure listed on the vehicle certification label (found on the driver’s door or door pillar).

Drive the vehicle at 20 mph (32 km/h) for at least two minutes. Make sure the warning light goes off. If the warning light stays on, there is a malfunction in the TPMS. See the appropriate manufacturer service information.

When the tire pressure warning light flashes for 20 to 30 seconds after a bulb-check has been performed and the message center displays warning messages, there is a malfunction in the TPMS. See the appropriate manufacturer service information.

Reset procedures

NOTE: The tire pressure monitoring system is not affected by wheel and tire rotation.

NOTE: If the tire pressure sensor is replaced, it will need to be trained. When the tire pressure warning light comes on and the message center displays “LOW TIRE PRESSURE,” check the air pressure of all tires and adjust to the specified cold pressure listed on the vehicle certification label (found on the driver’s door or the door pillar). Drive the vehicle at 20 mph (32 km/h) for at least two minutes. Make sure the warning light goes off.

Tire pressure sensor training

NOTE: In the following procedure, TPM Activation Tool (204-363) must be used.

NOTE: The tire pressure sensor training procedure must be done on a single vehicle, in an area without radio frequency (RF) noise and at least 3 feet (1 m) away from any other vehicle equipped with TPMS. RF noise is generated by electrical motor and appliance operation, cellular telephones and remote transmitters, power inverters and portable entertainment equipment.

NOTE: A new tire pressure sensor is shipped in an OFF mode (or battery saver mode), and must be turned ON before it can be trained. To turn on the sensor, inflate the tire to the recommended inflation pressure and wait at least two minutes, then continue with the sensor training procedure.

1) Turn the ignition switch to the OFF position, then press and release the brake pedal.

2) Turn the ignition switch from the OFF position to the RUN position three times, ending in the RUN position. Do not wait more than one minute between each key cycle.

3) Press and release the brake pedal.

4) Turn the ignition switch to the OFF position.

5) Turn the ignition switch from the OFF position to the RUN position three times, ending in the RUN position. Do not wait more than one minute between each key cycle.

NOTE: It may take up to six seconds to activate a tire pressure sensor. During this time, the activation tool must remain in place 180 degrees from the valve stem (see Figure 1).

NOTE: If a sensor does not respond to the activation tool, attempt to activate the same sensor using the activation tool. If the sensor still does not respond, move the vehicle to rotate the wheels at least one-fourth of a turn and attempt to activate the same sensor again.

NOTE: If the SJB does not recognize any one of the four tire pressure sensors during the tire training procedure, the horn will sound twice and the message center (if equipped) will display “TIRE NOT TRAINED REPEAT.” Repeat the training procedure from the beginning.

6) The horn will sound once and the tire pressure warning light will flash if the train mode has been entered successfully (if equipped, the message center displays “TRAIN LF TIRE”). Place the TPMS activation tool (204-363) on the left front tire wall opposite (180 degrees) from the valve stem. The horn will sound briefly to indicate that the tire pressure sensor has been recognized by the SJB.

NOTE: Do not wait more than two minutes between training each sensor.

7) Within two minutes after the horn sounds, place the activation tool on the right front tire wall opposite (180 degrees) from the valve stem. Repeat the procedure for the right rear and left rear tires (see Figure 2).

8) When the tire training procedure is complete, the message center (if equipped) will display “TIRE TRAINING MODE COMPLETE.” For vehicles not equipped with a message center, successful completion of the training procedure will be verified by turning the ignition switch to the OFF position without the horn sounding. If the horn sounds when ignition is turned off, the training procedure was not successful.

Demounting/mounting procedures

CAUTION: The tire should be demounted from the wheel using the tire changer manufacturer’s instructions. Use the following information to avoid damage during the demounting/mounting procedures.

CAUTION: The tire and wheel must always be correctly matched. It is very important to determine the size of each component before any assembly operations commence. Failure to adhere to these instructions can result in an explosive separation and cause serious bodily injury or death.

CAUTION: Use only wheels and wheel nuts that have been designed for the current model year Ford trucks. Tire pressure sensors are not designed to be used with aftermarket wheels. Aftermarket wheels or wheel nuts may not fit or function correctly, and can cause personal injury or damage to the vehicle. A wheel and tire assembly equipped with tire pressure sensor will have the following verbiage stamped or cast on the wheel: “Sensor May Be Inside.”

CAUTION: Retighten the wheel nuts at 500 miles (800 km) after any wheel change or any time the wheel nuts are loosened. Failure to retighten wheel nuts at the mileage specified can allow wheels to come off while the vehicle is in motion, possibly causing loss of vehicle control and collision.

NOTE: The use of run-flat tires when the vehicle is not originally equipped is not recommended, as it may cause the TPMS to malfunction.

NOTE: If possible, use a digital tire gauge (204-354) any time tire pressures are measured to be sure that accurate values are obtained. Ford recommends the use of a digital or dial-type tire pressure gauge rather than a stick-type gauge for increased accuracy.

To identify manufacturer part numbers for TPMS components, see the “Tire pressure monitor system components” table.

Tire pressure monitor system components

Application Part number

Tire pressure sensor/sensor kit 1A150/1A189

Strap/strap kit 1A177/1A193

Sensor cradle 1A175

Locking clip* 14C202

* Also part of Tire Pressure Sensor Kit (1A189).

Tire pressure sensor

CAUTION: Tire pressure sensors are manufactured in multiple colors based on their application. When installing a new sensor, make sure the color of the sensor being installed matches the color of the sensor that was removed. The different colored sensors are not interchangeable.

CAUTION: The tire pressure sensor is mounted to the wheel 180 degrees opposite of the valve stem, and is held in place by a stainless steel strap. Valve-mounted and strap-mounted tire pressure sensors are not compatible. Swapping wheels from one vehicle to another with the different systems will adversely affect TPMS operation.

NOTE: Tire pressure sensors are equipped with Lithium-ion batteries, and must be disposed of accordingly.

NOTE: The tire pressure sensor can be removed and installed without removing the strap or cradle.

Removal

1) Remove the wheel and tire assembly.

CAUTION: When using a paddle-type bead separator, ensure the valve stem is positioned at 6 o’clock to prevent damage to the tire pressure sensor. Some machines may have a nylon roller bead separator at the 12 o’clock position instead of the paddle-type bead separator at the 3 o’clock position.

CAUTION: DO NOT allow the tire beads to move beyond the wheel mid-plane when breaking the beads, or damage to the tire pressure sensor may occur.

2) Position the wheel and tire assembly on a suitable tire machine with the valve stem at the 6 o’clock or 12 o’clock position, and separate both beads of the tire from the wheel.

NOTE: Index mark the valve stem and wheel weight positions.

3) Place the wheel and tire assembly on the turntable of tire machine with the valve stem between the 5 o’clock and 6 o’clock positions, and the machine arm at the 12 o’clock position. Demount tire from wheel (see Figure 3).

CAUTION: Do not use a large screwdriver or apply excessive force in the following step, or damage to components will occur.

4) Using a pocket screwdriver, remove the sensor locking clip (see Figures 4 and 5). Detach the sensor from the cradle, and remove the sensor (see Figure 6).

Installation

CAUTION: If excessive force is applied during sensor installation, damage to the sensor can occur.

1) Position the sensor into the cradle by inserting the hinge end of the sensor into the hook end of the cradle, and pushing the opposite end of sensor down onto the cradle. Ensure the sensor is fully seated into the cradle (a “click” noise will be heard.) See Figure 7.

NOTE: The locking clip can only be fully seated when installed in the correct orientation.

If the locking clip cannot be fully inserted, the sensor may not be fully seated on the cradle or the locking clip may be inserted backward.

2) Insert a new locking clip into the sensor (see Figure 8).

3) Place the wheel on the turntable of the tire machine so that the tire pressure sensor is at the 6 o’clock position, and the valve stem and machine arm are at the 12 o’clock position.

CAUTION: Use only a soap and water solution to lubricate the tire.

Use of anything other than soap and water may result in damage to the tire pressure sensor.

4) Lubricate and mount the tire onto the wheel starting 90 degrees from the sensor, moving away from the sensor.

NOTE: A new tire pressure sensor is shipped in an OFF mode (or battery saver mode), and must be turned ON before it can be trained.

To turn the sensor on, inflate the tire to the recommended inflation pressure and wait at least two minutes, then continue with the sensor training procedure.

CAUTION: DO NOT inflate the tire higher than the maximum pressure stamped on tire sidewall.

5) Inflate the tire to the pressure specified on the vehicle certification label (located on the driver door or door pillar).

6) Install the wheel and tire assembly.

7) Train the tire pressure sensors. See reset procedures.

Tire pressure sensor strap and cradle

NOTE: While the tire pressure sensor is available separately, the cradle and strap are only available as a kit. Though there are several different strap kits available based on wheel diameter, all kits share the same base part number.

Removal

1) Remove the tire pressure sensor. WARNING: The strap is under tension. Always use safety goggles or a face shield and gloves when removing the band/strap to avoid personal injury.

2) To remove a dealer-installed strap, go to the next step. To remove a factory-installed strap, perform the following:

- Locate the strap buckle. Secure the strap to the wheel using duct tape on both sides of the buckle, about 0.98-inch (25 mm) from the buckle.

- Using a large screwdriver and a twisting motion, unbuckle the strap.

- Discard the strap.

3) To remove a dealer-installed strap, turn the worm gear screw until the strap is fully released from the worm gear. Discard the strap.

NOTE: To aid assembly, mark the location of the cradle prior to disassembly.

4) Using a screwdriver or similar tool, remove the cradle by inserting a screwdriver under the cradle and prying up.

Installation

1) Position the sensor into the new cradle by inserting the hinge end of the sensor into the hook end of the cradle and pushing the opposite end of the sensor down onto the cradle. Ensure the sensor is fully seated into the cradle (a “click” noise will be heard). See Figure 7.

NOTE: The sensor and cradle must be positioned with the hinge side of the sensor on the right side when viewed from the curb side (beauty side) of the wheel. The sensor has raised markings indicating how to position the sensor.

2) Clean the area where the sensor and cradle are to be installed. Remove the adhesive tape liner from the cradle, and position the sensor and cradle into the wheel drop well 180 degrees from the valve stem.

3) Install the tapered end of the strap through the opening of the cradle on the hinge side of the sensor. This will position the worm gear on the locking clip side of the sensor (see Figure 9).

CAUTION: Steel wheels have a “high spot” along their circumference. Ensure the strap is positioned in the lowest spot possible for correct sensor and cradle retention.

4) While keeping the strap parallel with the wheel flange, position the worm gear 0.5 inch to 1 inch (13 mm to 26 mm) away from the sensor (see Figure 9). Tighten the worm gear to 27 in.-lbs. (3 N.m).

5) Place the wheel on the turntable of the tire machine so that the tire pressure sensor is at the 6 o’clock position, and the valve stem and machine arm are at the 12 o’clock position.

CAUTION: Use only a soap and water solution to lubricate the tire. Use of anything other than soap and water may result in damage to the tire pressure sensor.

6) Lubricate and mount the tire onto the wheel starting 90 degrees from the sensor, moving away from the sensor.

NOTE: A new tire pressure sensor is shipped in an OFF mode (or battery saver mode), and must be turned ON before it can be trained.

To turn the sensor on, inflate the tire to the recommended inflation pressure and wait at least two minutes, then continue with the sensor training procedure.

7) Inflate the tire to the pressure specified on the vehicle certification label (located on the driver door or door pillar).

8) Install the wheel and tire assembly.

9) Train the tire pressure sensors. See reset procedures.

Retighten the wheel nuts at 500 miles (800 km) after any wheel change or any time the wheel nuts are loosened. Failure to retighten the wheel nuts at the mileage specified can allow the wheels to come off while the vehicle is in motion, possibly causing loss of vehicle control and collision. ?

Information for this column comes from Mitchell 1’s “Tire Pressure Monitoring Systems Guide” for domestic and import vehicles. Headquartered in Poway, Calif., Mitchell 1 has provided quality repair information solutions to the automotive industry for more than 80 years.

For more information, visit www.mitchell1.com. For archived TPMS articles, visit www.moderntiredealer.com.

To see more TPMS columns, click: