DESCRIPTION AND OPERATION

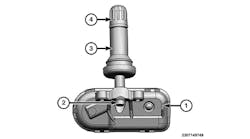

The tire pressure sensor is an integrated unit made up of a tire valve stem, a pressure sensor, and a transmitter. The tire pressure sensors are attached to the inside of each wheel, around the valve stem. The sensor transmits internal tire information using an RF (radio frequency) band wave signal one time per 60 seconds to the body control module. Each tire pressure sensor has its own tire pressure sensor ID to prevent jamming by similar systems on other vehicles.

Components: The system consists of the following components:

- Body control module

- Tire pressure sensors

- Initiators

- System indicator

The system is controlled by the body control module. If a vehicle is equipped with keyless access function, the initiator and the LF antenna are integrated.

Body Control Module: The body control module sends signals to the initiators and receives signals from the tire pressure sensor to verify pressure sensor IDs every time the vehicle is turned to the ON mode. It also receives signals from the transmitters for tire pressure, tire temperature, and the sensor battery condition, and it continuously monitors and controls the system.

Tire Pressure Sensor: The tire pressure sensor is an integrated unit made up of each tire valve stem, a pressure sensor, and a transmitter. The tire pressure sensors are attached to the inside of each wheel, around the valve stem. The sensor transmits internal tire information using an RF (radio frequency) band wave signal one time per 60 seconds to the body control module. Each tire pressure sensor has its own tire pressure sensor ID to prevent jamming by similar systems on other vehicles.

Initiator: The initiators are mounted on the top of each wheelwell. When the vehicle is turned to the ON mode, the initiators send an LF (low frequency) band wave signal to the tire pressure sensor, switching them from sleep mode to normal function mode. When the vehicle is turned to the OFF (LOCK) mode, the sensors switch from normal function mode back to sleep mode to extend their battery life.

Wheel: The TPMS will not work unless TPMS type wheels are installed on the vehicle. The original equipment wheels have a TPMS mark on them, and are counterweighted by adding material to counterbalance the weight of the tire pressure sensor.

MEMORIZING THE TIRE PRESSURE SENSOR ID

Procedure

NOTE:

- See the HDS Help menu for specific instructions.

- When replacing the body control module, use the HDS to memorize sensor IDs.

- After the sensor IDs are memorized, reduce the pressure in all four tires to less than the appropriate specification, and check to see that the four tire indicators come on.

Memorizing a Tire Pressure Sensor ID: All four sensor IDs must be memorized to the TPMS control unit whenever you do any of these actions:

- Replacing the body control module.

- Replacing the tire pressure sensor.

- Substituting a known-good wheel with tire pressure sensor.

NOTE:

- To ensure the TPMS control unit memorizes the correct sensor ID, the vehicle with the new tire pressure sensor must be at least 10 ft (3 m) away from other vehicles that have sensors.

- When replacing the body control module, use the HDS to memorize sensor IDs.

Memorizing a Tire Pressure Sensor ID Automatically: After rotating the tires or replacing a tire pressure sensor, drive the vehicle for at least 40 seconds at a speed of 15 mph (24 km/h) or more, and all the sensor IDs are memorized automatically.

NOTE: After the sensor IDs are memorized, reduce the pressure in all four tires to less than the specified tire pressure lower limit, and check to see that the four tire indicators come on.

Wheel Type and Specified Tire Pressure Lower Limit

18 inch wheel: 190 kPa (1.94 kgf/cm 2, 27.6 psi)

19 inch wheel: 195 kPa (1.99 kgf/cm 2, 28.3 psi)

Memorize a Tire Pressure Sensor ID with the HDS: The HDS can memorize the sensor ID of a new tire pressure sensor or a previously memorized sensor ID.

1. Turn the vehicle to the OFF (LOCK) mode.

2. Connect the HDS to the data link connector (DLC)

3. Turn the vehicle to the ON mode.

4. Make sure the HDS communicates with the vehicle and the TPMS control unit. If it does not communicate, go to the DLC circuit troubleshooting.

5. Memorize the tire pressure sensor ID by following the screen prompts on the HDS.

6. Turn the vehicle to the OFF (LOCK) mode.

REMOVAL AND INSTALLATION

Removal

NOTICE: Each tire pressure sensor contains a lithium anode battery that is not removable. The complete tire pressure sensor should be disposed of according to local battery disposal guidelines or requirements. An improperly disposed of battery can be harmful to the environment.

1. Remove the tire valve stem cap and the valve stem core to deflate the tire.

2. Remove any balance weights.

3. Break the bead loose from the wheel with a commercially available tire changer (A).

Note these items to avoid damaging the tire pressure sensor:

- Do the outside of the wheel first.

- Position the wheel as shown so the valve stem (B) is 90 degrees from the bead breaker (C) as shown in Fig. 1.

- Do not position the bead breaker of the tire changer too close to the rim.

4. Position the wheel as shown in Fig. 2 so that the tire machine (A) and the tire iron (B) are next to the valve stem (C), and will move away from it when the machine starts.

5. Remove the tire from the wheel.

6. Using the TORX bit (A), remove the TORX screw (B) and remove the tire pressure sensor housing (C) from the valve assembly (D) as shown in Fig. 3.

NOTE: Check the tire pressure sensor housing for any cracks, deforms or damages and replace it if necessary.

7. Cut around the valve bulb (A) like in Fig. 4 to make the removal of the valve assembly easier.

8. Pull out the valve assembly (A) as shown in Fig. 5 vertically through the rim hole using the commercially available valve stem puller tool (B).

NOTE: Do not remove the valve assembly before removing the tire pressure sensor housing.

Installation

1. Install the tire pressure sensor housing (A) on to the valve assembly (B) as shown in Fig. 6

Make sure the sensor housing is fully seated.

Install the TORX screw until the screw head is in contact with the sensor housing.

2. Install TORX screw (C) using the TORX bit (D) and the adjustable torque screwdriver (E) and tighten it to specifications, as shown in Fig. 6.

3. Before installing the tire pressure sensor, clean the mating surfaces on the sensor and the wheel.

4. Apply a mild soap and water solution to the valve insertion cone surface.

5. Insert the tire pressure sensor in the rim hole.

NOTE:

- Make sure there is no gap (C) between the valve bulb (D) and rim.

- Make sure the tire pressure sensor is installed within the angle that is shown in Fig. 7.

6. Install a commercially available valve stem puller tool (A) on the valve stem thread, as shown in Fig. 7, and pull the tire pressure sensor (B) straight through the rim hole perpendicularly to the rim hole.

7. Lube the tire bead sparingly with a paste-type tire mounting lubricant, and position the wheel as shown in Fig. 8 so that the tire machine (A) is next to the valve stem (B) and will move away from it when the machine starts.

8. Install the tire onto the wheel.

Make sure the tire bead is seated on both sides of the rim evenly.

9. With a dry air source, inflate the tire to 300 kPa (3.06 kgf/cm 2, 43.5 psi) to seat the tire bead to the rim.

10. Install the valve stem core and adjust the air pressure to the specifications listed on the door jamb.

11. Install the valve stem cap.

12. Check and adjust the wheel balance.

TORQUE SPECIFICATIONS

Description

Tire Pressure Sensor Nut

Specification

4-6 N.m (35-53 In-Lbs)