SUBJECT VEHICLES: Chrysler Jeep and Jeep Renegade, 2015 – 2017.

SPECIAL TOOLS NEEDED? A RKE-TPM 9936 analyzer may be used in conjunction with a scan tool.

The tire pressure monitoring system (TPMS) on 2015–2017 Chrysler Jeeps and Jeep Renegades is provided as standard on all models and shows the tire pressure values through a dedicated submenu in the instrument panel display.

Once the pressure value of a tire is influenced by deflation, the relative pressure value will flash in the instrument panel through the electronic vehicle information center (EVIC), which can be 3.5 inches or 7 inches (also called DID). The system also resets automatically after the wheels have been rotated, thus guaranteeing correct information about tire pressure and displaying it at all times in the EVIC. When tire pressure is 7-8 psi (48-55 kPa) below the specification listed on the label, the system emits an acoustic signal, illuminates the ISO low tire pressure warning light, and displays the pressure of the four active tires in the EVIC display. If a system fault is detected, the warning light will flash for 75 seconds, and then remains on continuously. Dashes will take the place of the pressure reading if a sensor is not correctly operating.

A five-sensor system is available for vehicles with a full-size spare wheel (in markets where provided).

The sensors wire lessly transmit tire pressure information at a frequency of 433 MHz. The tire pressure sensors send a tire pressure sensor value every 30 seconds when the vehicle is in motion and approximately every 13 hours when the vehicle is not in motion. The sensors also transmit a unique ID code to differentiate the sensors from those on nearby vehicles.

Tire pressure monitor warning indicators

The TPMS will warn the driver of a low tire pressure if the tire pressure falls below the low-pressure warning limit for any reason, including low temperature effects and natural pressure loss through the tire. The TPMS will continue to warn the driver of low tire pressure as long as the condition exists, and will not turn off until the tire pressure is at or above the recommended cold placard pressure.

Once the low tire pressure warning (tire pressure monitoring telltale light) illuminates, you must increase the tire pressure to the recommended cold placard pressure in order for the “tire pressure monitoring telltale light” to turn off. The system will automatically update and the tire pressure monitoring telltale light will turn off once the system receives the updated tire pressures.

The vehicle may need to be driven for up to 20 minutes above 15 mph (24 km/h) in order for the TPMS to receive this information.

TPMS reset procedures

NOTE: If a tire pressure sensor has been replaced, the tire pressure sensors must be retrained.

TPMS indicator

Once the low tire pressure warning (tire pressure monitoring telltale light) illuminates, you must increase the tire pressure to the recommended cold placard pressure in order for the tire pressure monitoring telltale light to turn off. The system will automatically update and the tire pressure monitoring telltale light will turn off once the system receives the updated tire pressures. The vehicle may need to be driven for up to 20 minutes above 15 mph (24 km/h) in order for the TPMS to receive this information.

TPMS sensors

NOTE: A new sensor ID can be programmed directly into the right front hub by using a RKE-TPM analyzer in conjunction with a scan tool. Once the new sensor ID has been programmed, the RKE-TPM analyzer can be used to update the TPMS by activating the sensor.

When a sensor is installed in a tire on the vehicle, the RF-Hub can automatically identify the sensor and its location during the first ensuing drive cycle. Identification will take approximately 10 minutes but the speed of the vehicle must exceed 15 mph (24 km/h). The TPM-RKE 9936 analyzer can also be used to program the new sensor identification number in the RF-Hub module. Scan each TPMS sensor at each road wheel, and store each sensor ID in the correct location (left front, left rear, right front, right rear). Connect the TPM-RKE analyzer tool to the scan tool. Then follow the programming steps outlined in the diagnostic scan tool for “Program Tire Pressure Sensor ID w/ TPM Tool.”

NOTE: The sensor IDs can also be programmed using a scan tool. Scan each TPMS sensor at each road wheel, and store each sensor ID in the correct location: left front, left rear, right front, right rear. Connect the scan tool. Then follow the programming steps outlined in the scan tool.

Demounting/mounting procedures

CAUTION: The tire should be demounted from the wheel using the tire changer manufacturer’s instructions. Use the following information to avoid damage during the demounting/mounting procedures.

CAUTION: The TPMS has been optimized for the original equipment tires and wheels. TPMS pressures have been established for the tire size equipped on the vehicle. Undesirable system operation or sensor damage may result when using replacement equipment that is not of the same size, type or style. Aftermarket wheels can cause sensor damage. Do not use aftermarket tire sealants or balance beads if the vehicle is equipped with TPMS, as damage to the sensors may result.

NOTE: If a tire pressure sensor has been replaced, the tire pressure sensors must be retrained. See “Reset procedures.”

NOTE: Wheels and tires are match-mounted at the factory. Before demounting a tire from its wheel, a reference mark should be placed on the tire at the valve stem location, to ensure that it is remounted in the original position on the wheel. For match-mounting procedures, refer to the appropriate manufacturer service information.

NOTE: Tire pressure may increase from 2 to 6 psi (14 to 41 kPa) during normal driving conditions. Do NOT reduce this normal pressure build up.

NOTE: If tires require leak-testing, a water test may be used to check for a leak around the sensor, as long as any water at the valve core is removed when the procedure is completed. Water can be expelled from the core area by pushing in on the core for several seconds, allowing escaping air to drive out any moisture. Re-inflate the tire as necessary. Install the original valve stem cap.

Tire pressure sensor

CAUTION: The sensors wirelessly transmit tire pressure information at a frequency of 433 MHz. Although additional sensors operating at 433 MHz are available and are used in other applications, they are not interchangeable. Always make sure the correct sensor is being used and be sure to replace the sensor with the correct part number.

CAUTION: The cap used on this valve stem contains an O-ring seal to prevent contamination and moisture from entering the valve stem. Retain this valve stem cap for reuse. Do not substitute a regular valve stem cap in its place.

CAUTION: Do not attempt to install a tire pressure sensor in an aftermarket wheel. Use tire pressure sensors in original style factory wheels only. If aftermarket wheels are installed, and therefore do not contain tire pressure sensors, the system will not function properly and the driver will be continuously notified of a system malfunction.

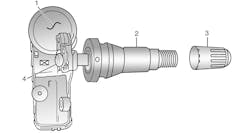

CAUTION: Any time a sensor is to be reinstalled in a wheel, a new valve stem assembly (2) must be installed to ensure air tight sealing (see Figure 1).

Removal

1) Remove the tire and wheel assembly from the vehicle.

2) Demount the tire from the wheel following the tire changer manufacturer’s instructions while paying special attention to the following to avoid damaging the pressure sensor:

When breaking the tire bead loose from the wheel rim, avoid using the bead breaker in the area of the sensor. That includes both the front and rear beads of the tire. Proceed to demount the tire from the wheel. Use this process on both the upper and lower tire beads.

3) Remove the sensor to the valve stem retainer screw (4) and then remove the sensor (1) from the valve stem (2) as seen in Figure 1 on page 100.

4) Remove the valve stem from the wheel (see Figure 1).

Installation

NOTE: If replacing the tire pressure sensor, a new valve stem may be pre-mounted to the sensor as an assembly. When reusing the tire pressure sensor, the new valve stem may come with a mounting screw.

1) Wipe the area clean around the sensor/valve stem mounting hole in the wheel. Make sure the surface of the wheel is not damaged.

2) Insert the new valve stem into the rim and pull through with a standard valve stem installation tool.

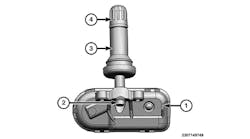

3) If replacing the valve stem only, verify that the flat sides of the brass extension on the bottom of the valve stem are at a 90 degree angle with the wheel (see Figure 2).4) Position the pressure sensor over the brass extension.

5) Install the retainer screw and torque to 12 in.-lbs.

6) Mount the tire on the wheel following the tire changer manufacturer’s instructions, paying special attention to the following to avoid damaging the tire pressure sensor:

Rotating wheel tire changers

Once the wheel is mounted to the changer, position the sensor valve stem approximately 280 degrees from the head of the changer in a clockwise direction before rotating the wheel (also in a clockwise direction) to mount the tire. Use this procedure on both the upper and lower tire beads (see Figure 3).Rotating tool tire changers

Position the wheel on the changer so that the sensor valve stem is approximately 210 degrees from the head of the changer in a clockwise direction from the mounting end of the tool (see Figure 4). Make sure the sensor is clear of the lower bead breaker area to avoid damaging the sensor when the breaker rises. Rotate the tool in a counterclockwise direction to mount the tire. Use this procedure on both the upper and lower tire beads.

7) Adjust air pressure to specification. Make sure the original style valve stem cap is securely installed to keep moisture out of the sensor. Install the wheel and tire assembly on the vehicle.

8) Drive the vehicle for a minimum of 5 minutes while maintaining a continuous speed above 20 mph (32 km/h). During this time, the system will learn the new sensor ID code and will clear any DTCs automatically.

If a sensor cannot be trained, see the appropriate manufacturer service information. ■

Information for this column comes from the tire pressure monitoring systems data in ProDemand®, Mitchell 1’s auto repair information software for domestic and import vehicles. Headquartered in Poway, Calif., Mitchell 1 has provided quality repair information solutions to the automotive industry since 1918. For more information, visit www.mitchell1.com.