SUBJECT VEHICLES: Kia Sorento 2011-2017

RELEARN PROCEDURE? Yes.

SPECIAL TOOLS NEEDED? Yes, a Kia GDS (Global Diagnostic System) with the TPMS module scan tool.

Illustrations courtesy of Kia Motors America Inc.

The tire pressure monitoring system (TPMS) on the 2011-2017 Kia Sorento monitors the air pressure in the four road tires with wheel-mounted tire pressure sensors. To do this, the system uses a TPMS receiver, four radio frequency (RF) tire pressure sensors, two warning indicators on the instrument cluster, and a data circuit to perform system functions.

The tire pressure sensor operates in two modes: stationary/rolling mode and sleep mode. In stationary/rolling mode, the sensor will measure pressure and temperature every four seconds, and measure acceleration every 60 seconds.

In sleep mode, the sensor enters a low current consumption state where no measurements are made in order to conserve battery power. All sensors are in this state when new. The sensor will not transmit unless requested to do so by the initiate command or when the vehicle accelerates to 15 mph (24 km/h).

Tire pressure monitor warning indicators

When tire pressure is below the allowed threshold, the low pressure indicator on the instrument cluster will be illuminated. If the system detects a receiver or sensor fault, or if it detects a fault that is external to the receiver or sensor, the TPMS warning indicator on the instrument cluster will be illuminated. If the fault is considered “critical,” the light will stay on throughout the entire ignition cycle.

Reset procedures

NOTE: If a tire pressure sensor is replaced, it will need to be initiated. The TPMS is not affected by wheel and tire rotation. The low tire pressure telltale illuminates when one or more tires is significantly underinflated. The indicator will go out after the tires are inflated to the specified pressure. Ensure the warning light goes off (this may take up to four minutes if the tire is not rapidly re-inflated).

Tire pressure sensor initiation

Auto-learn sensors

1) Every time the ignition is turned on, all sensor locations are verified and/or located.

2) If a sensor has been removed, the lack of response will cause it to eventually be removed from its list of active sensors (may take 10 minutes).

3) When new sensors are added, or the wheels are rotated, the system will automatically learn their new locations within 10 minutes after turning on the ignition if the vehicle is being operated at a speed of at least 15 mph (24 k/ph).

Manual sensor initiation

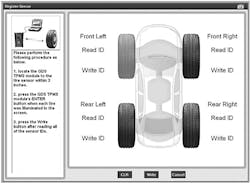

NOTE: In the following procedure, a Kia GDS (Global Diagnostic System) with the TPMS module scan tool must be used.

1) Condition – Ignition ON and Engine OFF

2) Holding TPMS module within 3 inches (76 mm) of the sensor valve, read each tire pressure sensor ID in the following order: front left, front right, rear left, then rear right.

3) Press the ENTER button as each tire is illuminated on the screen.

4) Press the WRITE button after reading all of the sensor IDs.5) Connect GDS to Data Link Connector (DLC) located under the left side of the instrument panel. Register the four sensor IDs to the receiver (see Figures 1 and 2).

NOTE: The TPMS receiver will complete the learn procedure of the new sensor after the vehicle is driven up to 20 minutes at speeds over 15 mph (24 km/h).

NOTE: For the system to correctly monitor the tires for under-inflation, there should be a total of exactly four sensors, one on each of the four road wheel positions. There should be no other sensors in the vehicle since this could cause the system to monitor the wrong sensors or fail to learn a new sensor.

6) Modify any sensor ID and press the [OK] button.

Demounting/mounting procedures

CAUTION: The tire should be demounted from the wheel using the tire changer manufacturer’s instructions. Use the following information to avoid damage during the demounting/mounting procedures.

CAUTION: Ensure that the wheel to be fitted is designed for the sensor mount. There should normally be a mark to indicate this.

NOTE: If a tire pressure sensor is replaced, it will need to be initiated. See “Reset procedures.” The TPMS is not affected by wheel and tire rotation.

Tire pressure sensor

CAUTION: Do not use puncture repair fluid, as this can cause the sensor pressure port to block and an incorrect warning to occur.

Removal

1) Remove the wheel and tire assembly.

CAUTION: Avoid tire/tool contact with the valve while demounting the tire.

2) Deflate tire and remove balance weights. The tire bead should be broken about 90 degrees from the valve side of the wheel. The bead breaker should not be set too deep. Demount should end near the valve.

CAUTION: The valve nut should not be re-used.

3) While handling the sensor with care, remove the valve nut.

4) Discard the valve assembly.Installation

CAUTION: Avoid bringing the tire pressure sensor in contact with lubricant. Always handle the tire pressure sensor carefully.

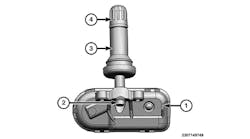

1) Assemble the valve to the sensor, and turn the valve three times with the square part of the screw in the slot (see Figure 3).

CAUTION: Ensure the sensor feet are against the wheel throughout the remainder of the assembly process.

2) Ensure that the valve hole and mating face of the wheel are clean. Mount the assembly to the wheel. The fit should not be tight (i.e., it should still be possible to easily adjust the valve angle).

CAUTION: Ensure the grommet remains in contact with the wheel.3) Tighten the washer and nut by hand until the valve thread meets the nut’s built-in calibrated stop (see Figure 4).

CAUTION: While tightening the nut, do not exceed the allowed torque. To avoid damage, do not use electric or pneumatic tools.

4) Using a torque wrench, tighten the nut to 35 in.-lbs. (4 N.m). It is normal to feel a break as the 20 in.-lbs. (2.3 N.m) calibrated stop in the nut snaps and the torque falls. Increase the torque smoothly in order to achieve a clean break of the stop.

5) Lubricate the tire bead (not the rim). Do not use excessive lubrication.

6) Start tire mounting about 5.9 inches (15 cm) from the valve. Move the mounting tool away from the valve. Avoid tire/tool contact with the valve. Finish with the mounting tool near the valve.

7) Adjust the inflation pressure of all wheels. Install the valve cap.

8) If your are installing a new sensor, initiate the tire pressure sensor. See “Reset procedures.” ■

Torque specifications

Component Ft.-lbs. (N.m)

Wheel nut 65-86 (90-120)

In.-lbs. (N.m)

Tire pressure sensor valve nut 1 35 (4)

It is normal to feel a break as the 20 in.-lbs. (2.3 N.m) calibrated stop in the nut snaps and the torque falls. Increase torque smoothly in order to achieve a clean break of the stop. Do not exceed allowed torque. Do not use electric or pneumatic tools.

Information for this column comes from Mitchell 1’s “Tire Pressure Monitoring Systems Guide” for domestic and import vehicles. Headquartered in Poway, Calif., Mitchell 1 has provided quality repair information solutions to the automotive industry for more than 80 years. For more information, visit www.mitchell1.com.

To read more TPMS columns, see:

Honda Pilot and Ridgeline, 2005-2016

TPMS: Acura ILX, MDX, RDX, TL, TLX, TSX and ZDX -- 2007 - 2016