Winter Tires and TPMS Systems: Follow Proper Procedures to Maintain Functionality

We’re fast approaching that time of the year when those of us who live in cold-weather areas get excited when the “s” word — snow — is in the forecast. It still means winter tire changeover time for us. The only thing better is a nice blizzard warning!

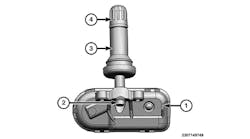

It’s common for many customers to switch to dedicated winter tires for their region’s cold/snow weather period. Obviously, they have several options, but some of them could potentially create tire pressure monitoring system (TPMS) issues. The most straightforward service is that the original or “summer” tires are demounted and the winter tires of the same size are mounted to the same wheels. Since a tire service is being performed, it’s best to take the opportunity to carefully inspect all TPMS sensors and service replacement parts to ensure proper sealing and battery performance after explaining your findings and getting a written go-ahead from the customer. The sensors may be pre-programmed or need to be programmed (depending on make and model of the sensors).

The winter tires should feature the same overall diameter as the OE tires in order for the ABS to function, so pay attention to the inflation pressure recommendation. If the inflation pressure is different, that would have to be reprogrammed to the TPMS ECU. As an aside, be sure to note the speed rating of the winter tires, too.

Once the wheel and tire assemblies have been installed on the vehicle, the sensors need to be relearned.

Different wheels and tires

However, some customers prefer to run different wheels with their winter tires, mostly for two reasons: to save the OE or aftermarket alloy wheels from salt, ice and slush, and for the ability to run a narrower tire with a taller sidewall, which is better suited for snow and ice traction and handling as compared to a wider tire with a shorter and less-compliant sidewall.

Tire size and rim diameter would be based on finding a size that is equal to the original tire overall diameter in order to provide the ABS module with the proper overall diameter and rotational distance, while being narrower and still providing a load index that is suitable for the vehicle. Be sure to consult fitment guides and check clearances for brakes, suspension, etc., before making any recommendations to your customer.Here’s an example. A vehicle is equipped with OEM alloy wheels and 205/55R16 tires. This size tire features an overall diameter of 24.9 inches. The customer wishes to move to steel wheels and a narrower winter tire with a taller sidewall.One potential choice would be 15 x 6 or 6.5-inch wheels with 195/65R15 winter tires. The fitment would still have an overall diameter of 25 inches, but with a narrower section width and taller sidewall.

In order for the TPMS to remain operational, TPMS sensors would need to be installed to the new steel wheels, using sensors that have stems compatible with the valve holes in the wheels. Once the sensors are programmed (along with any change to inflation pressure that may be needed), the assemblies are installed to the vehicle and relearned.Do not be tempted to install any wheel without a TPMS sensor on any vehicle that was originally equipped with direct TPMS. The National Highway Traffic Safety Administration’s (NHTSA) interpretation of the Motor Vehicle Safety Act prohibits service providers from installing aftermarket tire and wheel assemblies without working TPMS sensors.

Depending on your state, the TPMS might not need to be functional in order to pass an inspection, but a shop is not allowed to omit the sensors on a vehicle that was equipped with TPMS. The real question you need to ask yourself is what type of professionalism do you portray if you give your customers their vehicle back with a TPMS light glaring at them every time they drive it?

Upgrading tires and changing placard value

The process is quite simple. For direct-TPMS, using the appropriate scan tool that allows this reprogramming function, select the mode that enables tire pressure value resetting (the steps will vary depending on the make and model of tool), change the factory OEM values to the new desired values, again following the prompts on the specific tool in use.

Once the system has been reprogrammed to alert based on a new inflation pressure value, fill out a supplemental tire cold inflation pressure placard and attach it near the factory tire placard. Include the new tire size, load rating and new cold inflation pressure.

TPMS module replacement

After replacing modules that contain TPMS data, it is required to relearn TPMS data. It’s interesting to note that on Ford vehicles, proper module programming and TPMS relearning is required.

The vehicle’s dome lamp will flash until all needed programming and relearning is complete.

Tip for sensor programming

Be sure to program sensors away from where other sensors in your inventory are stored. Multiple sensors might be programmed by mistake. Whenever you are changing out tire/wheels as a set, make sure that you have moved the original tire/wheels with their TPMS sensors from your work area. This will help avoid having the wrong sensor being programmed, with the customer coming back to your shop a day later with the TPMS light illuminated.

Typically, a flashing TPMS light indicates a TPMS fault and a solid light indicates a tire pressure issue. To make sure that there is not a system fault, cycling the key is necessary. Once driven for a time, the flashing light will go solid.

Cycling the key will reset the system and allow for either a solid or flashing light. It’s best practice to relearn the TPMS anytime the wheels are removed.

You never know if the “last guy” rotated the wheel/tire assemblies and did not perform a relearn.

Relearning tips

Once one or more TPMS sensors have been replaced, or a service such as tire/wheel rotation has been performed, a relearn procedure is likely required.

There are three basic types of relearns, depending on the make, model and year vehicle. These include auto-relearn, stationary relearn and OBD II relearn.Auto Relearn applies to vehicles that are designed to learn sensor IDs without the need for a TPMS tool. Once the service has been performed, the vehicle simply needs to be driven for a predetermined amount of time in order for the system to reset.

Depending on the vehicle, this may require as little as 5 minutes to as long as perhaps 20 minutes. However, to prevent wasting time, use a TPMS tool to trigger each sensor to verify that the sensors are functioning properly.

It should be obvious that all tires must first be inflated to the placard’s recommended pressure.

A Stationary Relearn allows sensor IDs to be transferred to the vehicle ECU while in the shop. This typically requires a TPMS tool or an OBD II scan tool.

An RF signal communicates with the ECU to inform the computer as to the location of each sensor wheel position.

ATEQ provided this example. It is a 2014 Ford Escape that features a standard ignition. Inflate all tires to the specification, turn the ignition off, press and release the brake pedal, cycle the ignition off to run three times, finishing with the engine in the run position. Next, press and release the brake pedal again, and then turn the ignition to the off position.

Once again, cycle the ignition from off to run three times, finishing with the engine in the run position. At this point, the horn will sound twice (at least, it should).

Use the tool to activate the left front sensor, at which point the horn should sound once. Repeat this process for the right front sensor, followed by the right rear sensor, followed by the left rear sensor.

The sequence must be followed properly (LF, RF, RR, LR).The OBD II Relearn requires a TPMS tool to transfer the new sensor IDs directly to the vehicle’s ECU. With the tool connected to the OBD II port, each sensor is scanned, following the prompts on the tool.

The sensor IDs are then transferred to the ECU. Most Asian and European vehicles currently require the OBD II relearn procedure.

Referring to a 2011 Toyota Camry as an example, the procedure is as follows:

1. Inflate all tires to specification.

2. Read all sensor IDs using a scan tool.

3. Connect the tool to the OBD port.

4. Reset the ECU using the tool.

5. Turn the ignition off, then to the on position.

6. Drive the vehicle at a speed of about 12 mph for about five minutes.

This is merely one example. Always follow the procedure provided by the auto maker’s service manual or the instructions provided by the sensor and/or tool maker. ■