DESCRIPTION & OPERATION

When the tire pressure warning system detects that the tire pressure of a tire is lower than the threshold, it will inform the driver using a warning light.

The tire pressure warning ECU and receiver receives the transmitter ID, temperature and tire pressure information from the tire pressure warning valve and transmitters. This information is used to determine when the pressure in one of the tires has dropped.

TIRE PRESSURE WARNING RESET SWITCH

By operating the tire pressure warning reset switch, the tire pressure warning ECU and receiver can be set to issue a warning at an inflation pressure that corresponds to the type of tires fitted to the vehicle.

Operate the tire pressure warning reset switch only after the inflation pressures of all tires (except the compact spare tire) have been adjusted on the vehicle.

DESCRIPTION OF INITIALIZATION

During initialization, the tire pressure warning valve and transmitters measure the inflation pressure of the tires, and register the signals that are transmitted into the tire pressure warning ECU and receiver at a frequency of about once per minute. The initialization process is completed when signals from all tires (except the compact spare tire) have been received.

Perform initialization in the following cases (and only after the transmitter ID registration is completed.)

- Before delivery of a new vehicle.

- After replacement of the tire pressure warning ECU and receiver.

- After replacement of a tire pressure warning valve and transmitter.

- When the specified tire pressure changes due to the use of a different size or type of tire.

- When the specified tire pressure changes due to a change in the vehicle load, the speed range that the vehicle will be used in, etc.

- When a tire rotation is performed and the specified tire pressures are different for the front and rear of the vehicle.

TROUBLESHOOTING

Things to consider when the tire pressure warning light illuminates:

When the tire pressure warning light does not go off, or when it illuminates during driving, check the tire pressure. If the tire pressure warning light illuminates within several hours after adjusting the tire pressure, a tire may have a slow air leak.

The system is disabled under the following conditions: (When the condition returns to normal, the system will work properly.)

- When all the tire and wheel assemblies that have tire pressure warning valve and transmitters registered with the tire pressure warning ECU and receiver have not been installed.

- When all the transmitter ID codes are not registered with the tire pressure warning ECU and receiver.

- When the tire pressure warning valve and transmitter battery is depleted (Battery life is 10 years).

The system may become disabled under the following conditions:

- When electric devices or facilities using similar radio frequencies are nearby.

- When a wireless device or other equipment operating at a similar frequency is in use in the vehicle.

- When a window tint that affects radio wave signals is installed.

- When there is a lot of snow or ice on the vehicle, particularly around the wheels or wheel housing.

- When non-genuine wheels are used.

- When tire chains are used.

- When aftermarket tire repair sealant is used.

WARNING: After use of tire repair sealant, replacement of the tire pressure warning valve and transmitter is required to ensure normal system operation. Normal system operation cannot be ensured by only repairing or replacing the tire.

In normal mode, DTCs are stored in the tire pressure warning ECU and receiver and output by blinking the tire pressure warning light or by using the Techstream.

By switching from normal mode into test mode (signal check mode), the tire pressure warning ECU and receiver, each tire pressure warning valve and transmitter and tire pressure warning reset switch can be inspected.

MEMORIZING THE TIRE PRESSURE SENSOR ID

REGISTRATION PROCESS

The transmitter ID is written on the tire pressure warning valve and transmitter. It is not possible to read the transmitter ID after installing the tire onto the wheel. Therefore, make a note of the transmitter ID before installing the tire.

Make sure to perform ID registration using the Techstream after replacing the tire pressure warning ECU and receiver.

BEFORE REGISTRATION

When replacing the tire pressure warning ECU and receiver, read the transmitter IDs and number of the transmitters (4 or 5) stored in the old ECU using the Techstream and write them down.

If reading the stored transmitter IDs is impossible due to malfunctions of components such as the tire pressure warning ECU and receiver, remove the tires from the wheels and check the IDs located on the tire pressure warning valve and transmitters.

REGISTER TRANSMITTER ID (USING TECHSTREAM)

The previously registered IDs will be cleared from memory when registration is completed. If the ID registration step is not completed within 300 seconds, ID registration will be canceled.

- Set the tire pressure to the specified value.

- Turn the engine switch off.

- Connect the Techstream to the DLC3.

- Turn the engine switch on (IG).

- Turn the Techstream on.

- Enter the following menus: Chassis / Tire Pressure Monitor / Utility /ID Registration/Tire Number Registration.

- Perform the procedure displayed on the Techstream. The number of registered tire pressure warning valves and transmitters can only be set to four when the value is currently set to 5. The number of registered tire pressure warning valves and transmitters should only be changed from the default value when requested by the customer.

CONFIRMATION OF REGISTRATION (USING TECHSTREAM)

If the automatic ID registration is started while DTC C2126 is stored, DTC C2126 and C2128 are stored in the tire pressure warning ECU and receiver.

During registration, DTC C2128 is stored by the tire pressure warning ECU and receiver and the tire pressure warning light blinks for one minute then illuminates. When the tire pressure warning ECU and receiver successfully receives signals from all the transmitters whose IDs are stored in the ECU, DTC C2128 is cleared and the tire pressure warning light turns off.

If a tire pressure warning valve and transmitter of the same type is carried in the vehicle, registration may not be completed.

REGISTER TRANSMITTER ID (USING AUTOMATIC ID REGISTRATION FUNCTION)

When registration is complete, all previously registered IDs are cleared.

If DTCs C2176, C2179 and U0129 are stored, registration mode cannot be entered.

If the Techstream is being used to display the data list, registration mode cannot be entered.

If the Techstream is used to display the data list during registration, registration will be canceled.

If DTCs C2176, C2179 and U0129 are stored during registration, registration will be canceled.

If the engine switch is turned off before the vehicle is driven after entering registration mode, registration will be canceled.

- Adjust the tire pressure in all tires to the specified pressure.

- Turn the engine switch off and stop the vehicle for 15 minutes or more. (After stopping the vehicle for 15 minutes or more, the frequency of electrical wave signals sent by the tire pressure warning valve and transmitters increases for the first few minutes of driving — eight times the normal frequency.)

- Turn the tire pressure warning reset switch on and off three times within three seconds (pressed / released / pressed / released / pressed / released). The tire pressure warning ECU and receiver switches to ID registration mode according to the automatic ID registration function.

During registration, the tire pressure warning light blinks for one minute before turning on, the multi-information display tire pressure displays as "- -" and "Registering Each TPWS Sensor" is displayed. (TPWS is an abbreviation for Tire Pressure Warning System.)

- Drive at approximately 25 mph for approximately 10 to 30 minutes during one trip. Do not drive the vehicle in reverse during registration. If the vehicle is driven in reverse the information may be reset before registration completes, and registration may take longer than normal to complete.

- During the procedure, make two or more right or left turns.

- When registration is completed, the tire pressure warning light turns off, the normal tire pressure is displayed on the multi-information display and "Registering Each TPWS Sensor" stops displaying.

Registration may take longer than normal in the following situations:

- If the vehicle is stopped frequently or stopped for long period of time.

- If the vehicle is driven in reverse or is driven on rough roads or uneven surfaces.

- If The vehicle is driven near another vehicle with the same type of tire pressure warning valve and transmitter installed for a long period of time.

- If the vehicle was not stopped for 15 minutes or more before registration.

- If the vehicle is driven at 25 mph or less for a long period of time, or if the engine switch is turned off during ID registration.

INITIALIZATION

Before initialization, refer to the link as the procedure for adjusting the tire pressures differs depending on the temperature of the tires. Set the tire pressure to the specified value.

INITIALIZATION PROCEDURE

- Turn the engine switch on (IG).

- Press and hold the tire pressure warning reset switch for three seconds or more until the tire pressure warning light blinks three times.

- Turn the engine switch off.

- Connect the Techstream to the DLC3.

- Turn the engine switch on (IG).

- Turn the Techstream on.

- Enter the following menus: Chassis / Tire Pressure Monitor / Data List. (Note: It may take a few minutes until the values are displayed.) The wheel position cannot be determined from ID1 through ID4 on the Data List.

- Check that initialization has been completed.

- Confirm that the tire pressure data of all tires is displayed on the Techstream screen.

SENSOR REMOVAL AND INSTALLATION

REMOVAL

Remove wheel assembly, and then remove the tire pressure warning valve and transmitter.

- Remove (but keep) the tire valve cap.

- Remove the valve core to release the air from the tire. Make sure that a sufficient amount of air has been released.

- Using an 11 mm deep socket wrench, remove the nut and washer.

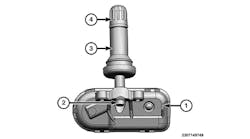

- Drop the tire pressure warning valve and transmitter with grommet into the tire. The grommet may remain attached to the wheel. Be careful not to damage the tire pressure warning valve and transmitter due to interference between the valve and the tire bead. Set the tire remover shoe as shown in the illustration. (Fig 2)

- Using a tire remover, remove the tire from the disc wheel.

- Take out the tire pressure warning valve and transmitter with grommet from the tire.

- Remove the grommet from the tire pressure warning valve and transmitter.

- Using a T10 "TORX" socket wrench, remove the bolt and tire pressure monitor sensor from the tubeless tire valve.

INSTALLATION

General Tips:

Always use a new bolt, grommet, tubeless tire valve and valve core when installing the tire pressure warning valve and transmitter.

Check that the washer and nut are not damaged and replace them if necessary.

Make sure not to damage the urethane covered backside of the tire pressure warning valve and transmitter (the surface opposite to the side with the ID code) with anything sharp.

Write down the ID number before installation.

Check that there is no oil, water or lubricant around the wheel hole, tire pressure warning valve and transmitter, washer and nut. Failing to do so may result in improper installation.

Use only a specified tire valve cap. If an unspecified tire valve cap is used, it may seize to the tire pressure warning valve and transmitter.

Install tire pressure warning valve and transmitter

- Using a T10 "TORX" socket wrench, install the tire pressure monitor sensor to the new tubeless tire valve with a new bolt. Torque: 1.2 N*m (12 kgf*cm, 11 in.*lbf)

- Install a new grommet to the tire pressure warning valve and transmitter. (A new tire pressure warning valve and transmitter comes with a grommet installed. Make sure not to install an extra grommet.)

- Write down the seven-digit transmitter ID number shown in Fig. 4.

- Insert the tire pressure warning valve and transmitter with grommet from the inside of the wheel.

NOTE: Make sure that the tire pressure warning valve and transmitter are installed so the printed surface can be seen. If the tire pressure warning valve and transmitter is installed upside down, it may be damaged or fail to transmit signals when driving at high speeds. Check for any deformation or damage to the tire pressure warning valve and transmitter. Ensure there is no foreign matter on the grommet and around the wheel hole. No further tightening is required once the nut is tightened to the specified torque.

- Install the washer to the tire pressure warning valve and transmitter from the outside of the rim, and using an 11 mm deep socket wrench, tighten the nut. Torque: 4.0 N*m (41 kgf*cm, 35 in.*lbf) Make sure there is no foreign matter on the grommet, washer and nut. If the tire pressure warning valve and transmitter is positioned outside of the proper area, it will interfere with the tire bead and may be damaged.

- Set the tire and disc wheel onto the mounting machine as shown in Fig. 6.

- Apply a sufficient coat of soapy water or equivalent to the tire bead and rim. Do not apply soapy water or its equivalent directly to the tire pressure warning valve and transmitter.

- Make sure that the tire bead and mount tool do not interfere with the tire pressure warning valve and transmitter.

- Using a mounting machine, install the tire to the disc wheel.

- Install a new valve core.

- Inflate the tire to the specified tire inflation pressure.

- After the tire is inflated, the nut may be loose. Using an 11 mm deep socket wrench, retighten the nut to the specified torque.

- Check the surroundings of the tire pressure warning valve and transmitter for air leaks with soapy water or equivalent. If air is leaking from the valve core, press the valve core several times to remove foreign matter. Replace the valve core as necessary. If air is leaking from around the tire pressure warning valve and transmitter, check if the grommet, washer and nut are not deformed, damaged or contaminated with foreign matter. Replace as necessary.

- Install the tire valve cap.

Complete the installation process by installing the wheel assembly, inspect tires, register transmitter ID, inspect the tire pressure warning system, and perform initialization.

TORQUE SPECIFICATIONS

N*m kgf*cm, in.*lbf

TPMS ECU and receiver set bolt 8.3 (85, 73)

TPMS valve and transmitter set bolt 1.2 (12, 11)

TPMS valve and transmitter set nut 4.0 (41, 35)