DESCRIPTION & OPERATION

The tire pressure sensor is integrated with a valve and installed in each wheel. The sensor detects tire air pressure and tire temperature and transmits the detected air pressure and tire temperature in the form of a radio signal to the BCM.

WARNING: Radio waves could adversely affect electrical medical equipment. Those who use a pacemaker should contact the electrical medical equipment manufacturer for possible influences before use.

The low tire pressure warning lamp blinks for one minute, then turns ON when any malfunction occurs except low tire pressure. Erase the self-diagnosis memories for Tire Pressure Monitoring System (TPMS), or register the ID to turn low tire pressure warning lamp OFF.

ID registration is required when replacing or rotating wheels, replacing tire pressure sensor or BCM.

When inflating the tires, park the vehicle in the safe area and ensure the safety of the working area. Read and understand the easy fill tire alert function prior to use. Inflate the tires one at a time.

If there is no response for approximately 15 seconds or more after inflating the tires, cancel the use of the easy fill tire alert function or move the vehicle approximately 3.2 feet backward or forward to try again. The air filler pressure may be weak or out of service area. Despite the high-precision TPMS pressure sensor, an indicated value may differ from that of the pressure gauge.

Air pressure is measured rather high due to the rise in tire air temperature after driving. If TPMS is malfunctioning, the easy fill tire alert is unusable.

Replace the screw, the tire pressure sensor, the valve, the valve core, and the valve cap as a set when replacing each tire.

Do not apply excessive force to the valve and tire pressure sensor when adjusting tire pressure.

Because the tire pressure sensor conforms to North America radio law, the sensor may be used only in North America and used only for the specified method. It should not be disassembled or modified. Do not install a tire pressure sensor from other cars. The TPMS does not function if the specified Genuine Nissan tire pressure sensor is not installed.

MEMORIZING THE TIRE PRESSURE SENSOR ID

Work Procedure

This procedure must be performed after replacement of a transmitter or BCM. TPMS ID registration can be performed using one of the following procedures:

Transmitter Activation tool [KV48105501 (J-45295-A)] using CONSULT (preferred method)

Signal Tech II tool [- (J-50190)] using CONSULT (preferred method)

Signal Tech II tool [- (J-50190)] without CONSULT

CONSULT only

TPMS REGISTRATION WITH TRANSMITTER ACTIVATION TOOL [KV48105501 (J-45295-A)]

1) Ignition switch ON.

2) Select "ID REGIST" in "Work support" mode of "AIR PRESSURE MONITOR".

3) Select "Start" on "ID REGIST" screen.

4) Hold the transmitter activation tool [KV48105501 (J-45295-A)] (1) against the side of the left front tire, near the valve stem.

5) With the tool held at a 0 to 15 degree angle to the tire, press and hold the transmitter activation tool button until the indicator lamp turns OFF (approximately 5 seconds).

6) Repeat steps 4 and 5 for the remaining tires in this order: right front, right rear and left rear.

7) When ID registration is complete, check the following pattern at each wheel:

| Sequence | ID registration position | Turn signal lamp | CONSULT |

| 1 | Front LH | 2 blinks | "Yet (red)" "Done (green)" |

| 2 | Front RH | ||

| 3 | Rear RH | ||

| 4 | Rear LH |

8) After the ID registration procedure for all wheels is complete, press "End" to finish ID registration.

9) Test drive the vehicle to ensure that the TPMS lamp is OFF and no warning messages are present.

TPMS REGISTRATION WITH SIGNAL TECH II TOOL [- (J-50190)]

NOTE: The Signal Tech II must be updated with the newest software version in order to perform these procedures. The Signal Tech II software updates can only be downloaded from a CONSULT unit. Other versions will not show the updates.

1) Adjust the tire pressure for all tires to the recommended value.

2) Ignition switch ON.

3) Select "ID REGIST" in "Work support" mode of "AIR PRESSURE MONITOR".

4) Select "Start" on "ID REGIST" screen.

5) Turn on the Signal Tech II tool [- (J-50190)].

6) Hold the Signal Tech II against the side of the left front tire, near the valve stem.

7) With the tool held at a 0 to 15 degree angle to the tire, select "Activate Sensor" from the main menu, then press and release the "OK" button to activate the sensor. Once the sensor is activated, the vehicle parking lamps will flash and the sensor ID will appear on the CONSULT screen.

8) Repeat steps 6 and 7 for the remaining tires in this order: right front, right rear and left rear.

9) When ID registration is complete, check the pattern at each wheel from the chart in the above section.

10) Once all sensors have been activated, select "End" to finish ID registration.

11) Test drive the vehicle to ensure that the TPMS lamp is OFF and no warning messages are present.

WITHOUT CONSULT

1) Adjust the tire pressure for all tires to the recommended value.

2) Turn on the Signal Tech II tool [- (J-50190)] and select "TPMS Check" from the main menu.

3) Select vehicle model and year.

4) When prompted, hold the Signal Tech II against the side of the left front tire, near the valve stem.

5) With the tool held at a 0 to 15 degree angle to the tire, press and release the "OK" button to activate the sensor. Once the sensor is activated, the tool will sound a tone and the tire pressure will be displayed.

6) Repeat steps 4 and 5 for the remaining tires in this order: right front, right rear and left rear.

7) When prompted, connect the tool to the data link connector. The tool will connect to the BCM, read the VIN, read sensor IDs and check for TPMS DTCs. Along with DTCs detected, one of the following will be displayed next to each wheel:

N/A - Not applicable because no ID found by the tool

OK - Wheel and sensor are in original position

NEW - New ID found compared to BCM

RT - Wheel has been rotated

Low Press - Low tire pressure

8) If no DTC is present or the repair has been completed, press the "OK" button to register the IDs and clear DTCs.

9) Test drive the vehicle to ensure that the TPMS lamp is OFF and no warning messages are present.

10) Print a Signal Tech II Audit Report for your records. Refer to the Signal Tech II User Guide for instructions.

TPMS REGISTRATION WITH CONSULT ONLY

1) Adjust the tire pressure for all wheels to match the list below:

| Tire position | Tire pressure kPa (kg/cm2 , psi) |

| Front LH | 240 (2.4, 35) |

| Front RH | 220 (2.2, 32) |

| Rear RH | 200 (2.0, 29) |

| Rear LH | 180 (1.8, 26) |

2) Ignition switch ON.

3) Select "ID REGIST" in "Work support" mode of "AIR PRESSURE MONITOR".

4) Select "Start" on "ID REGIST" screen.

5) Drive the vehicle at a speed greater than 40 km/h (25 MPH) for 3 minutes or more.

6) After ID registration for all wheels is complete, press "End" to finish ID registration.

7) Adjust the tire pressures for all tires to the recommended value.

8) Test drive the vehicle to ensure that the TPMS lamp is OFF and no warning messages are present.

TIRE PRESSURE SENSOR REMOVAL AND INSTALLATION

REMOVAL

1) Remove the wheel and tire using power tool.

NOTE: If the tire is to be reused, apply a matching mark on the tire in line with the position of the valve hole in the wheel for the purpose of wheel and tire balance adjustment after installation.

2) Remove the valve cap and the valve core to deflate the tire.

CAUTION: Do not use silicone lubricant. Use of silicone lubricant will deteriorate the tire and wheel. Do not damage the wheel.

3) Lubricate the tire outside bead well with a suitable non-silicone lubricant and separate the tire outside bead from the wheel.

4) Lubricate the tire inside bead well with a suitable non-silicone lubricant and separate the tire inside bead from the wheel.

NOTE: To avoid damage to the vehicle, the tire must not slip or spin on the wheel when demounting or mounting a tire's outer bead. Damage to the wheel or the tire pressure sensor could result.

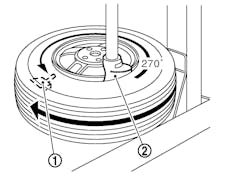

5) Carefully lift and set the wheel and tire onto the tire changer turntable so that the tire pressure sensor (1) is at the bottom. Position the wheel and tire so that the tire pressure sensor is 270 degrees from the mounting/demounting head (2).

Fig 3

6) Remove the tire from the wheel.

CAUTION: Do not drop or strike the tire pressure sensor. Replace the tire pressure sensor if it has been dropped from higher than one meter.

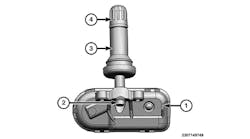

7) Remove the screw (A) and the tire pressure sensor (1) from the valve (2).

Fig 4

8) Cut the inner end (A) of the valve using a suitable tool (B).

Fig 5

CAUTION: Do not damage the wheel. Pull the valve straight through the wheel hole.

9) Remove the valve from the wheel.

INSTALLATION

CAUTION: Do not loosen the screw if the tire pressure sensor and the valve are being replaced as an assembly. Make sure there are no burrs, foreign substances, or indications of damage to the wheel.

1) Clean the valve hole in the wheel.

2) When reusing the tire pressure sensor, install the tire pressure sensor to the valve using the following procedure. (Do not reuse the valve.)

a) Install the tire pressure sensor (1) to the roll pin (A) of the valve (2).

Fig 6

CAUTION: Do not drop or strike the tire pressure sensor. Replace the tire pressure sensor if it has been dropped from higher than one meter.

b) Install the screw to the tire pressure sensor and tighten to the specified torque. CAUTION: Do not reuse the screw.

3) Apply a suitable non-silicone lubricant to the surface of the valve that touches the wheel and to the valve hole in the wheel.

CAUTION: Do not use silicone lubricant. Use of silicone lubricant will deteriorate the tire and wheel. Do not allow lubricant to contact the air pressure detection hole.

4) Position the tire pressure sensor assembly (1) on the wheel (2).

Fig 7

CAUTION: Do not damage the tire pressure sensor. Do not allow lubricant to contact the air pressure detection hole. The tire pressure sensor must be oriented tangentially to the rim of the wheel.

5) Install the tire pressure sensor assembly to the wheel.

CAUTION: Do not damage the wheel. Install the valve all the way to the wheel. Make sure the valve seats properly in the valve hole in the wheel.

6) Check the tire pressure sensor assembly (1) position. The tire pressure sensor assembly must be installed to the wheel (2) as shown.

Fig 8

CAUTION: Do not damage the wheel or the tire pressure sensor. The tire pressure sensor must be oriented tangentially to the rim of the wheel. If the tire pressure sensor unit position is not correct, rotate the tire pressure sensor unit to the correct position using Tool.

7) Apply a suitable non-silicone lubricant to the tire inside bead.

CAUTION: Do not use silicone lubricant. Use of silicone lubricant will deteriorate the tire and wheel. Do not allow lubricant to contact the air pressure detection hole.

8) Install the tire inside bead onto the wheel in the position shown.

Fig 9

CAUTION: Do not damage the wheel or the tire pressure sensor. Do not allow the tire beads to make contact with the tire pressure sensor. Do not touch the tire pressure sensor with the mounting head.

9) Place the wheel on the turntable of the tire machine. Make sure that the tire pressure sensor (1) is 270 degrees from the mounting/dismounting head (2).

CAUTION: Do not use silicone lubricant. Use of silicone lubricant will deteriorate the tire and wheel. Do not allow lubricant to make contact with the tire pressure sensor.

10) Apply a suitable non-silicone lubricant to the tire outside bead.

NOTE: If the tire is being reused, align the matching mark applied on the tire with the position of the valve hole in the wheel for the purpose of wheel and tire balance adjustment after installation. To avoid damage to the vehicle, the tire must not slip or spin on the wheel when demounting or mounting a tire's outer bead. Damage to the wheel or the tire pressure sensor could result.

11) Install the tire outside bead onto the wheel as normal.

12) Install the valve core. (Do not reuse the valve core.)

13) Inflate the tire.

14) Install the valve cap. (Do not reuse the valve cap.)

15) Balance the wheel and tire.

16) Install the wheel and tire in the appropriate position on the vehicle.

When replacing the tire pressure sensor, perform the "TIRE PRESSURE SENSOR ID REGISTRATION."

Fig 10 and 11 – use both for torque specifications