DESCRIPTION AND OPERATION

The tire pressure monitoring system (TPMS) warns the driver when a significant loss of tire pressure occurs in any of the equipped tires. The Tire Fill Alert (TFA) (if equipped) feature provides visual and audible alerts to drivers to assist in inflating an underinflated tire to the recommended tire pressure without the need to check a gauge or the instrument panel. TFA only functions once the tire pressure is low enough to trigger the telltale on the dashboard.

When the driver starts filling the underinflated tire, the corner lamp nearest to that tire will begin to flash. When the recommended pressure is reached, the horn sounds once and the turn signal lamps will stop flashing and briefly turn solid. If the tire is overinflated by more than five psi, the horn will sound multiple times and the turn signal lamp will continue to flash for several seconds after filling stops. To release and correct the pressure, while the turn signal lamp is still flashing, briefly press the center of the valve stem. When the recommended pressure is reached, the horn sounds once.

If a new sensor has been installed or tire rotated, the vehicle must be stationary for about 20 minutes before the system can start the process of calculating correct sensor locations. For this to happen, the vehicle will need to be driven at a speed greater than 12 mph for about 10 minutes. When the vehicle is stationary, a sensor’s internal shock sensor is inactive which puts the sensors into a stationary state. In this state the sensors sample tire pressure once every 30 seconds and do not transmit at all if the tire pressure does not change. Once vehicle speed is greater than 25 mph, the sensors begin to transmit once a minute keeping the pressure data up to date.

Each sensor has its own unique identification code which it transmits as part of each RF message and must be learned into the BCM memory. Once all four IDs have been learned and vehicle speed is greater than 25 mph, the BCM continuously compares IDs and pressure data in the received transmissions to the learned IDs and pressures to determine if all four sensors are present and if one or more tires are low.

If the BCM detects a low tire pressure condition, or a malfunction in the system, it will send a serial data message to the instrument cluster requesting the appropriate tire pressure monitor indicator illumination and also to display the appropriate data message on the driver information center, if equipped. The sensors continuously compare their last pressure sample to their current pressure sample and will transmit in Alert mode if a 1.2 psi change in tire pressure has been detected in either a stationary or rolling state.

When the tire pressure system detects a significant loss or gain of tire pressure, the tire pressure monitor indicator icon is continuously illuminated on the instrument cluster and if equipped, a check tire pressure type message is displayed on the driver information center. Both the indicator icon and driver information center message can be cleared by adjusting the tire pressures to the recommended psi.

If power is disconnected from the BCM or if the vehicle battery is disconnected each tire pressure sensor ID is retained but all of the tire pressure information is lost. Under these circumstances the BCM cannot assume that the tire pressures were maintained over an unknown period. To reactivate the sensors, the vehicle must be driven above 25 mph for at least two minutes. When the sensors are activated, the driver information center displays the current tire pressures. The EL-52545 tire pressure monitor sensor and RF diagnostic tool may also be used to activate the sensors as well.

The Importance of Proper Tire Inflation

When you inflate the tires to the recommended inflation pressures, the factory-installed wheels and tires are designed to handle loads to the tire's rated load capacity. Incorrect tire pressures, or under-inflated tires, can cause vehicle handling concerns, poor fuel economy, shortened tire life and tire overloading.

Inspect the tire pressure when the following conditions apply:

- The vehicle has been sitting at least three hours.

- The vehicle has not been driven for more than one mile.

- The tires are cool.

Tires with a higher than recommended pressure can cause the following conditions: a hard ride, tire bruising, and rapid tread wear at the center of the tire.

Tires with a lower than recommended pressure can cause the following conditions: a tire squeal on turns, hard steering, rapid wear and uneven wear on the edge of the tread, tire wheel bruises and tire wheel rupture, tire cord breakage, high tire temperatures, reduced vehicle handling, high fuel consumption and soft riding.

Unequal pressure on the same axle can cause uneven braking, steering lead and reduced vehicle handling.

Refer to the Tire Placard for specific tire and wheel applications and tire pressures.

TIRE PRESSURE INDICATOR SENSOR LEARN

Make sure the TPMS tool’s battery is sufficient to complete TPMS learn process. Do not place the tool directly on the valve stem. The tool should be placed against the tire sidewall near the valve stem. The sensor learn activation procedure may have to be repeated up to three times before determining a sensor is malfunctioning.

Tire Pressure Sensor Learn with EL-52545 (Preferred)

The EL-52545 allows the tire pressure sensors to be learned without transmitting RF data between the tire pressure sensors and the vehicle. When using the EL-52545 each tire pressure sensor ID is learned to the EL-52545 and stored internally. The EL-52545 is then connected to the vehicle DLC using the OBD2 Interface Module, which is part of the EL-52545 kit. The stored tire pressure sensor information will then be loaded into the K9 Body Control Module. Using the EL-52545 to learn tire pressure sensors will prevent the vehicle from learning errant nearby tire pressure sensors from other vehicles, especially if the tire pressure sensor batteries are low. This is the GM recommended method.

1) Turn on EL-52545

2) Select RDR from the on-screen display

3) If available, scan the QR code on the vehicle's tire placard or certification label. If QR is not available, select MMY from the on-screen display and manually input the vehicle information.

4) Approach the vehicle starting with the left front tire and read each tire pressure sensor information by pressing the green trigger button with the EL-52545 located near the tire valve stem. Read each tire pressure sensor in the order identified on the EL-52545.

If any sensors display "Sensor Not Compatible" on the EL-52545 screen, you will need to first make sure compatible sensors are installed on the vehicle.

5) If any tire pressure sensors do not respond, replace the sensor only after several attempts have been made to identify all sensors. An undetected sensor will be identified with "No Sensor Detected" displayed in the table. After sensor replacement rerun RDR procedure.

6) Verify the BAT value for each tire pressure sensor in the table on the EL-52545 is OK. If not OK, replace the sensor and rerun RDR procedure.

7) Verify the pressure and temperature values are reasonable based on the ambient conditions and actual tire pressure. If either value is inaccurate, replace the tire pressure sensor and rerun RDR procedure.

8) Ignition On/Vehicle in Service Mode.

9) Connect the EL-52545 OBD2 Interface Module to the EL-52545 .

10) Verify the OBDII icon is displayed on the EL-52545 and the green com LED is flashing on the EL-52545 OBD2 Interface Module.

11) Connect the other end of the OBD2 Interface Module to the vehicle DLC.

12) Select OK on the EL-52545 and follow the on-screen instructions.

Tire Pressure Sensor Learn with EL-50448 (Alternative)

When EL-50448 Tire Pressure Monitor Sensor Activation Tool is used in activate mode, it produces a low frequency transmission that activates the sensor. The sensor responds to a low frequency activation by transmitting in Learn Mode-Remotely Triggered. When the BCM receives a learn mode transmission while in Learn mode, it will assign that sensors ID to the location on the vehicle relative to the order in which it was learned.

In the event a particular sensor is activated and the horn does not chirp, it may be necessary to rotate the wheel so that the valve stem is in a different position due to the sensor signal being blocked by another component.

1) Ignition On/Vehicle in Service Mode, using driver information center buttons or scan tool (if available), initiate the Tire Pressure Sensors Learn mode. A double horn chirp will sound indicating the Learn mode has been enabled. The left front turn signal will also be illuminated.

2) Starting with the left front tire, activate the sensor by holding the antenna of the tire pressure monitor activation tool aimed upward against the tire sidewall close to the wheel rim at the valve stem location. Press and release the activate button. Ensure that the transmit indicator on the tool indicates that the sensor activation signal is being transmitted. Wait for a horn chirp. If the horn does not chirp, repeat the sensor activation sequence with the tool. Once the horn chirp has sounded, the sensor information is learned and the turn signal in the next location to be learned will illuminate.

3) After the horn chirp has sounded and the right front turn signal is illuminated, repeat step three for the remaining three sensors in the following order: Right front, right rear and left rear.

4) When the left rear sensor has been learned and a double horn chirp has sounded, the learn process is complete and the BCM exits the Learn mode.

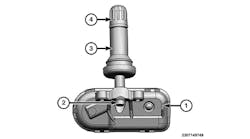

SENSOR REMOVAL AND INSTALLATION

Removal Procedure

1) Raise and support the vehicle.

2) Remove the tire and wheel assembly.

3) Demount the tire from the wheel.

4) If a tire sealant product was used/found within the tire/wheel, use a mild dish soap, clean water and shop cloths to remove the sealant residue from the tire and wheel surfaces.

5) Use a suitable tool inserted into the hole of the tire valve front and rear stem to prevent it from rotating.

6) Remove and discard the tire pressure indicator sensor bolt.

7) Remove the tire pressure indicator sensor by pulling it straight off of the tire valve front and rear stem.

Do not scratch or damage the clear coating on aluminum wheels with the tire changing equipment. Scratching the clear coating could cause the aluminum wheel to corrode and the clear coating to peel from the wheel.

8) Remove and discard the tire valve front and rear stem by pulling it through the wheel.

Installation Procedure

Never install the tire pressure indicator sensor on unapproved wheels. Whenever the Tire Pressure Indicator Sensor is removed from the wheel, install a new tire valve front and rear stem and a new bolt. Do not reuse the old parts.

1) Before installation, verify the orientation of the tire valve front and rear stem for the correct position of the tire pressure indicator sensor.

2) Remove the new bolt from the new tire pressure indicator sensor and pull it straight off the new tire valve front and rear stem.

3) Apply lubricant to the new tire valve front and rear stem.

4) Using a tire valve stem installation tool, pull the tire valve front and rear stem through in a direction parallel to the valve hole on the wheel.

Ensure the flat of the valve lines up with the flats of the snap in the enclosure.

5) Assemble the tire pressure indicator sensor to the new tire valve front and rear stem.

6) Use a suitable tool inserted into the hole of the tire valve front and rear stem to prevent it from rotating.

7) Install and tighten the new tire pressure indicator sensor bolt.

8) Check that the tire valve front and rear stem is concentric and completely seated in the valve stem hole of the wheel.

9) Make sure that there is a gap between the tire valve front and rear stem and the tire pressure indicator sensor.

The tire should not have contact with the tire pressure indicator sensor during installation to prevent damage of the tire pressure indicator sensor.

10) Mount the tire to the wheel.

11) Inflate the tire to the specified pressure as stated on the tire placard.

12) Install the new dust cap.

13) Install the tire and wheel assembly.

14) Perform the tire pressure indicator sensor learn procedure.

15) Remove the support and lower the vehicle.