DESCRIPTION & OPERATION

SYSTEM DESCRIPTION [09/2019 - ]

- When the tire pressure warning system detects that the tire pressure of a tire is lower than the threshold, it will inform the driver using a warning light. The tire pressure warning ECU and receiver receives the transmitter ID, temperature and tire pressure information from the tire pressure warning valve and transmitters. This information is used to determine when the pressure in one of the tires has dropped.

- Description of Tire Position Identification Function (with Tire Inflation Pressure Display Function): The tire inflation pressure display function displays the position and pressure of each tire on the multi-information display. The tire position can be identified using any of the following three methods:

a. Using the Techstream, manually enter the tire position for each transmitter ID.

b. Perform initialization to clear the existing tire position information, then drive the vehicle at 23 mph or more for 10 minutes or more until each tire position is automatically identified.

Note: Identifying the tire position automatically without performing initialization by driving the vehicle as normal may take longer than other methods. The previous tire positions will be displayed until they are automatically updated.

c. Without performing initialization, drive the vehicle as normal until each tire position is automatically updated.

3. Description of Registration: When tires and wheels are replaced, always ensure that each transmitter ID is correctly registered.

When one or more of the tire pressure warning valve and transmitters or the tire pressure warning ECU and receiver is replaced, the transmitter IDs for all of the tire pressure warning valve and transmitters must be re-registered. Before registering the transmitter ID of the new tire pressure warning valve and transmitter, check the Data List and record all of the transmitter IDs that are already registered.

4. Tire Pressure Warning Reset Switch: By operating the tire pressure warning reset switch, the tire pressure warning ECU and receiver can be set to issue a warning at an inflation pressure that corresponds to the type of tires fitted to the vehicle. Therefore, the warning threshold must be set to the proper value in order to comply with local regulations. Operate the tire pressure warning reset switch only after the inflation pressures of all tires (except the compact spare tire) have been adjusted on the vehicle.

5. Description of Initialization: During initialization, the tire pressure warning valve and transmitters measure the inflation pressure of the tires and register the signals that are transmitted into the tire pressure warning ECU and receiver at a frequency of about once per minute. The initialization process is completed when signals from all tires (except the compact spare tire) have been received.

Perform initialization in the following cases:

a. Before delivery of a new vehicle.

b. After replacement of the tire pressure warning ECU and receiver.

c. After replacement of a tire pressure warning valve and transmitter.

d. When the specified tire pressure changes due to the use of a different size or type of tire.

e. When the specified tire pressure changes due to a change in the vehicle load, the speed range that the vehicle will be used in, etc.

f. When a tire rotation is performed and the specified tire pressures are different for the front and rear of the vehicle. (Perform initialization after the transmitter ID registration is completed.)

TPMS REGISTRATION PROCEDURES

REGISTRATION PROCEDURE [09/2019 - ]

The transmitter ID is written on the tire pressure warning valve and transmitter. It is not possible to read the transmitter ID after installing the tire onto the wheel. Therefore, make a note of the transmitter ID before installing the tire.

1. Before Registration:

a. In case of tire pressure warning ECU and receiver replacement:

- Read the registered transmitter IDs that are stored in the old ECU using the Techstream and write them down.

- If reading the stored transmitter IDs is impossible due to malfunctions of components such as the tire pressure warning ECU and receiver, remove the tires from the wheels and check the IDs located on the tire pressure warning valve and transmitters.

b. In case of tire pressure warning valve and transmitter replacement, take a note of the seven-digit number (transmitter ID) written on the tire pressure warning valve and transmitter.

2. Register Transmitter ID (Using Techstream): The previously registered IDs will be cleared from memory when registration is completed. If the ID registration step is not completed within 300 seconds, ID registration will be canceled.

a. Set the tire pressure to the specified value.

b. Turn the ignition switch off.

c. Connect the Techstream to the DLC3.

d. Turn the ignition switch to ON and the Techstream on.

e. Enter the following menus: Chassis / Tire Pressure Monitor / Utility / ID Registration.

f. Perform the procedure displayed on the Techstream.

It may take a few minutes until the values are displayed. If the values are not displayed after a few minutes, perform troubleshooting according to the inspection procedure for DTCs C2121 to C2124.

If the transmitter IDs have not been registered, DTC C2171 is stored in the tire pressure warning ECU and receiver after three minutes or more.

If normal pressure values are displayed, the transmitter IDs have been registered correctly.

If the tire pressure values are not displayed after a few minutes, the transmitter IDs may be incorrect or the system may have a malfunction.

After all transmitter IDs are registered, DTC C2126 is stored in the tire pressure warning ECU and receiver and the tire pressure warning light blinks for 1 minute and then illuminates. When the tire pressure warning ECU and receiver successfully receives signals from all the transmitters whose IDs are stored in the ECU, DTC C2126 is cleared and the tire pressure warning light goes off.

3. Confirmation of Transmitter ID Registration: Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

It may take a few minutes until the values are displayed. If the values are not displayed after a few minutes, perform troubleshooting according to the inspection procedure for DTCs C2121 to C2124.

Reduce the tire inflation pressure of each tire 5.8 psi or more within 30 seconds, and check that the "ID Tire Inflation Pressure" data is updated and that the actual tire inflation pressures are displayed.

After confirming that all of the tire inflation pressure values (except the compact spare tire) have been updated, adjust the tire inflation pressure to the specified value, press the tire pressure warning reset switch and perform initialization.

4. Tire Position Identification (Using Techstream) (with Tire Inflation Pressure Display Function):

a. Set the tire pressure to the specified value.

b. Turn the ignition switch off.

c. Connect the Techstream to the DLC3.

d. Turn the ignition switch to ON and the Techstream on.

e. Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

Note: It may take a few minutes until the values are displayed. When an "ID Tire Inflation Pressure" value has not changed, reset the tire pressure to the appropriate specified value and rotate the tire 90 to 270 degrees. Then rapidly release the tire pressure and recheck the value.

f. Rapidly reduce the tire pressure for each wheel at least 5.8 psi within 30 seconds.

g. Read the "ID Tire Inflation Pressure" value and identify the tire with reduced pressure, and record the corresponding tire pressure warning valve and transmitter (ID1 to ID4).

h. Repeat for each tire.

i. Set the tire pressure to the specified value.

j. Enter the following menus: Chassis / Tire Pressure Monitor / Utility / Tire Position Write.

k. Perform the procedure displayed on the Techstream.

5. Tire Position Identification (Not Using Techstream) (w/ Tire Inflation Pressure Display Function):

a. Set the tire pressure to the specified value.

b. The tire position can be automatically identified using any of the following two methods:

- Perform initialization to clear the existing tire position information, then drive the vehicle at 23 mph or more for 10 minutes or more until each tire position is automatically identified.

Note: Identifying the tire position automatically without performing initialization by driving the vehicle as normal may take longer than other methods. The previous tire positions will be displayed until they are automatically updated.

- Without performing initialization, drive the vehicle as normal until each tire position is automatically updated.

MEMORIZING THE TIRE PRESSURE SENSOR ID

INITIALIZATION [09/2019 - ]

Initialization can only be performed for vehicles with a tire pressure warning reset switch.

If initialization is performed, the existing tire positions will be cleared, but will be automatically identified when the vehicle is driven at 23 mph or more for 10 minutes or more.

Initialization can be confirmed through the tire pressure warning light.

The order in which the data is received is random.

If the signals from all the tire pressure warning valve and transmitters are received, initialization is completed.

Initialization is completed when the Data List "ID Tire Inflation Pressure" display shows the correct pressures

Initialization is normally completed within a few minutes.

It may take a few minutes until the values are displayed. If the values are not displayed after a few minutes, perform troubleshooting according to the inspection procedure for DTCs C2121 to C2124.

If initialization has not been completed successfully, DTC C2177 is stored after a vehicle speed of 37 km/h (23 mph) or more is detected for 20 minutes or more.

During test mode (sensor check mode), the system will not change to initialization mode even if the tire pressure warning reset switch is pushed.

1.Before Initialization:

Make sure that the tires are cool and set the tire pressure to the specified value.

2. Initialization Procedure:

a. Turn the ignition switch to ON.

b. Press and hold the tire pressure warning reset switch for three seconds or more until the tire pressure warning light blinks three times.

c. Turn the ignition switch off.

d. Connect the Techstream to the DLC3.

e. Turn the ignition switch to ON and turn the Techstream on.

f. Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

g. Check that initialization has been completed.

h. Confirm that the tire pressure data of all tires is displayed on the Techstream screen.

TIRE PRESSURE SENSOR REMOVAL AND INSTALLATION

REMOVAL [08/2015 - ]

1.Remove front wheel.

2. Remove rear wheel.

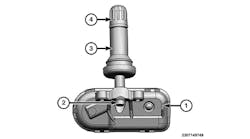

3. Remove tire pressure warning valve and transmitter (for Type A).

a. Remove, but keep, the tire valve cap. Make sure that a sufficient amount of air has been released.

b. Remove the valve core to release the air from the tire.

Be careful not to damage the tire pressure warning valve and transmitter due to interference between the valve and the tire bead.

c. Using a tire remover, remove the tire from the disc wheel.

d. Using a T10 "TORX" driver, remove the bolt and tire pressure monitor sensor from the tubeless tire valve.

e. Cut the tubeless tire valve and remove it by pulling from the outer side of the disc wheel.

4.Remove Tire Pressure Warning Valve And Transmitter (for Type B).

a. Remove, but keep, the tire valve cap. Make sure that a sufficient amount of air has been released.

b. Remove the valve core to release the air from the tire.

c. Using an 11 mm deep socket wrench, remove the nut and washer.

d. Drop the tire pressure warning valve and transmitter with grommet into the tire. ( The grommet may remain attached to the rim.)

Be careful not to damage the tire pressure warning valve and transmitter due to interference between the valve and the tire bead. Set the tire remover shoe as shown in the illustration.

e. Using a tire remover, remove the tire from the disc wheel.

f. Take out the tire pressure warning valve and transmitter with grommet from the tire.

g. Remove the grommet from the tire pressure warning valve and transmitter.

INSTALLATION [08/2015 - ]

Always use a new bolt, tubeless tire valve and valve core when installing the tire pressure warning valve and transmitter.

Make sure not to damage the urethane covered backside of the tire pressure warning valve and transmitter (the surface opposite to the side with the ID code) with anything sharp.

Write down the ID number before installation.

Check that there is no oil, water or lubricant around the rim hole and tire pressure warning valve and transmitter. Failing to do so may result in improper installation.

Use only a specified tire valve cap. If an unspecified tire valve cap is used, it may seize to the tire pressure warning valve and transmitter.

The tire pressure warning valve and transmitter cannot be installed to steel wheels. Make sure to check the wheel type before installation.

1,Precaution (for Type A):

Always use a new grommet and valve core when installing the tire pressure warning valve and transmitter.

Check that the washer and nut are not damaged, and replace it if necessary.

Make sure not to damage the urethane covered backside of the tire pressure warning valve and transmitter (the surface opposite to the side with the ID code) with anything sharp.

Write down the ID number before installation.

Check that there is no oil, water or lubricant around the rim hole, tire pressure warning valve and transmitter, washer and nut. Failing to do so may result in improper installation.

Use only a specified tire valve cap. If an unspecified tire valve cap is used, it may seize to the tire pressure warning valve and transmitter.

2. Precaution (for Type B)

3. Install Tire Pressure Warning Valve and Transmitter (for Type A)

a. Using a T10 "TORX" socket wrench, install the tire pressure monitor sensor to the new tubeless tire valve with a new bolt. Torque: 1.2 N*m (12 kgf*cm, 11 in.*lbf)

b. Write down the seven-digit transmitter ID number shown in the illustration.

Make sure that the tire pressure warning valve and transmitter is installed so that the printed surface can be seen. If the tire pressure warning valve and transmitter is installed upside down, it may be damaged or fail to transmit signals when driving at high speeds.

Check that there is no deformation or damage to the tire pressure warning valve and transmitter.

Check that there is no foreign matter on the around the rim hole.

c. Install the tire pressure warning valve and transmitter from the inside of the rim.

Position the main body of the tire pressure warning valve and transmitter in the area shown in the illustration.

If the tire pressure warning valve and transmitter is positioned outside this area, it will interfere with the tire bead and may be damaged.

d. Set the tire and disc wheel onto the mounting machine as shown in the illustration.

Do not apply soapy water or equivalent directly to the tire pressure warning valve and transmitter.

e. Apply a sufficient coat of soapy water or equivalent to the tire bead and rim.

Make sure that the tire bead and mount tool do not interfere with the tire pressure warning valve and transmitter.

Make sure that the tire pressure warning valve and transmitter is not clamped by the bead and rim.

f. Using a mounting machine, install the tire to the disc wheel.

g. Install a new valve core.

h. Inflate the tire to the specified tire inflation pressure.

i. Check the surroundings of the tire pressure warning valve and transmitter for air leaks with soapy water or equivalent.

-

- If air is leaking from the valve core, press the valve core several times to remove foreign matter. Replace the valve core as necessary.

- If air is leaking from around the tire pressure warning valve and transmitter, check if the tubeless tire valve is not deformed, damaged or contaminated with foreign matter. Replace the tubeless tire valve as necessary.

j. Install the tire valve cap.

4. INSTALL TIRE PRESSURE WARNING VALVE AND TRANSMITTER (for Type B)

A new tire pressure warning valve and transmitter comes with a grommet installed. Make sure not to install an extra grommet.

a. Install a new grommet to the tire pressure warning valve and transmitter.

b. Write down the seven-digit transmitter ID number.

Make sure that the tire pressure warning valve and transmitter is installed so that the printed surface can be seen. If the tire pressure warning valve and transmitter is installed upside down, it may be damaged or fail to transmit signals when driving at high speeds.

Check that there is no deformation or damage to the tire pressure warning valve and transmitter.

Check that there is no foreign matter on the grommet and around the rim hole.

c. Insert the tire pressure warning valve and transmitter with grommet from the inside of the rim.

No further tightening is required once the nut is tightened to the specified torque. Check that there is no foreign matter on the grommet, washer and nut.

d. Install the washer to the tire pressure warning valve and transmitter from the outside of the rim, and using an 11 mm deep socket wrench, tighten the nut. Torque: 4.0 N*m (41 kgf*cm, 35 in.*lbf)

Position the main body of the tire pressure warning valve and transmitter in the area shown in the illustration.

If the tire pressure warning valve and transmitter is positioned outside this area, it will interfere with the tire bead and may be damaged.

e. Set the tire and disc wheel onto the mounting machine as shown in the illustration.

Do not apply soapy water or equivalent directly to the tire pressure warning valve and transmitter.

f. Apply a sufficient coat of soapy water or equivalent to the tire bead and rim.

Make sure that the tire bead and mount tool do not interfere with the tire pressure warning valve and transmitter.

Make sure that the tire pressure warning valve and transmitter is not clamped by the bead and rim.

g. Using a mounting machine, install the tire to the disc wheel.

h. Install a new valve core.

i. Inflate the tire to the specified tire inflation pressure.

No further tightening is required once the nut is tightened to the specified torque.

j. After the tire is inflated, the nut may be loose. Using an 11 mm deep socket wrench, retighten the nut to the specified torque. Torque: 4.0 N*m (41 kgf*cm, 35 in.*lbf)

k. Check the surroundings of the tire pressure warning valve and transmitter for air leaks with soapy water or equivalent.

-

- If air is leaking from the valve core, press the valve core several times to remove foreign matter. Replace the valve core as necessary.

- If air is leaking from around the tire pressure warning valve and transmitter, check if the grommet, washer and nut are not deformed, damaged or contaminated with foreign matter. Replace the grommet, washer or nut as necessary.

l. Install the tire valve cap.

5. Install Front Wheel Torque: 113 N*m (1152 kgf*cm, 83 ft.*lbf)

6. Install Rear Wheel Torque: 113 N*m (1152 kgf*cm, 83 ft.*lbf)

7. Inspect tires.

8. Register Transmitter ID.

9. Perform Initialization.

10. Inspect Tire Pressure Warning System.